Electrical discharge machining , or EDM for short, is a highly accurate machining process during which sparks, or electrical discharges, shape a workpiece by removing material. Read More…

XACT Wire EDM Corp. is one of the largest and most experienced Wire EDM Companies in the country. Our Wire EDM manufacturing capabilities include a large number of high-end machines with two locations offering advanced CMM and video inspection. We work with a wide variety of customers in the medical, defense, aerospace, automation, robotics industries as well as many companies in the metal...

Twin City is ISO 9001:2000 certified for all simple & complex EDM services, in addition to many other services & their forte is producing difficult, complex parts through their state-of-the-art equipment & highly skilled staff. TC will perform the nearly impossible & is known to give both 100% in quality & service. Our flexibility & versatility provide customers with affordable convenience.

At B&B Precision Wire EDM, Inc., we take pride in delivering cutting-edge EDM solutions that redefine precision and efficiency. With a relentless commitment to excellence, our team crafts a diverse range of EDM products that cater to the evolving needs of industries worldwide.

AMI Machining, Inc. takes pride in our unwavering commitment to excellence in the realm of Electrical Discharge Machining (EDM). We have consistently been at the forefront of innovation and precision in the manufacturing industry.

Conventional electronic discharge machining and wire EDM machining take place here at Aerospace Techniques. We machine items that are "out of the norm" due to complexity, material or shape. Since 1965, our machining services have been used for aerospace, aircraft engine and medical customers. Contact Aerospace Techniques today to get a quote for your next project!

More EDM Companies

Applications of EDM

Electrical discharge machining finds applications in various industries due to its ability to produce precise and intricate components. In aerospace, EDM is utilized to create critical engine and aircraft components with tight tolerances and complex geometries, such as turbine blades and fuel nozzles. The automotive sector, for instance, benefits from EDM for producing molds and dies for automotive parts, enabling the mass production of intricate components like gears, transmission parts, and engine components.

In the defense industry, meanwhile, EDM is used to manufacture specialized components for military vehicles, weapons systems, and aircraft, ensuring accuracy and reliability in mission-critical applications. The extrusion industry also employs EDM for producing molds for plastic and metal extrusion, enabling the production of various profiles and shapes used in construction, transportation, and industrial applications.

In electronics, EDM is instrumental in creating precise molds for semiconductor packaging, as well as manufacturing microelectromechanical systems (MEMS) and small-scale electronic components. The food and beverage industry additionally benefits from EDM in the production of molds for chocolate and confectionery, allowing for intricate and attractive designs on the final products.

In the medical field, EDM is extensively used for manufacturing surgical tools, implants, and dental components with high precision, ensuring better patient outcomes and enhanced medical procedures. Furthermore, the stamping industry relies on EDM to produce dies for sheet metal stamping, enabling the mass production of complex and accurate parts used in various applications, from household appliances to industrial equipment.

Overall, electrical discharge machining plays a crucial role in a wide range of industries, enabling the production of complex and high-precision components that are essential for advancing technology, improving manufacturing processes, and enhancing product performance across various sectors.

History

In 1770, Joseph Priestley discovered that one can create erosion using electrical discharge. We now know this effect as electro-discharge erosion.

Nearly 200 years after Priestley’s observation, a pair of Soviet researchers took the first steps towards developing modern EDM machining technology. The scientists, named N.I. Lazarenko and B.R. Butinzky, respectively, while doing other research, discovered that they could control sparking-induced erosion of tungsten electrical contacts by immersing electrodes in dielectric fluid. (Electrodes are conductive materials through which electricity may pass.) Spurred on by this discovery, the scientists decided to create a machine that used electrodes and dielectric fluid to help them work with tungsten and other challenging materials. They named their machine the resistor-capacitor circuit (RC circuit) type machine, or R-C-type machine for short. RC circuits charge electrodes.

Meanwhile, around the same time in the United States, a team of American scientists created another EDM machine that worked with electrodes. They used their technology to pull broken taps and broken drills from aluminum castings. Using machines featuring electrodes, strong sparking units, automatic spark repetition, an electromagnetic interrupter arrangement, and fluid replacement, they found success. Their first successful machines could generate up to 60 sparks per second.

Years later, other scientists improved upon their design by swapping in vacuum tube circuits. With these, their EDM machines could produce thousands of sparks per second and produce die-cuts at a breathtaking speed.

During the 1960s, engineers in the United States and the Soviet Union raced to be the first to develop wire cut EDM machinery. Wire cut EDM machines use a wire as a tool electrode. Engineers wanted to use EDM wire cut machinery to create hardened steel die tools.

In 1967, the Soviets came out with the first commercially viable numerically controlled (NC) wire cut EDM machine. Numerical control was the predecessor of computer numerical control. In 1974, an American group captained by David H. Dulebohn developed the first wire cut EDM machine that used CNC technology to plot lines. Two years later, Dulebohn improved upon the CN wire cut EDM machine with the first CNC controlled wire-cut EDM machine.

During the ‘70s, engineers and scientists began trying to figure out just how and why electrical discharge machining works. One of the first to take a stab at it was Frans Van Dijck, who in 1973 wrote a PhD thesis that used math to explain it. By Van Dijck’s own admission, though, a lot of his work was built on assumptions, not empirical evidence. In 1989, students at Texas A&M University continued the study. They put forth the claim, with a fair amount of evidence to back it, that EDM works via thermal processing.

No one has yet come forth with a claim backed by enough evidence for us to say with certainty why EDM works. Nevertheless, today, electrical discharge machining has improved by leaps and bounds. With it, manufacturers are now able to create highly accurate cuts, intricate surface markings, and finishes on all sorts of materials. They are also able to do so at rates of which early EDM developers could have only dreamed. EDM manufacturers are also actively working to stop the easy erosion of graphite electrodes. The industry is and will continue to be important, as intricate designs and cuts on metals are a necessity to successful electronics.

Process Components and Details

Electrical discharge machining (EDM) tools and equipment consist of several essential components, including the electrode, wire or shaped tool, and the power source, all working together to perform the EDM process.

The electrode is a crucial part of the EDM setup. It can be made of graphite or copper and serves as the tool that shapes the workpiece. During the process, the electrode comes into contact with the workpiece, and an electric discharge occurs between them. As a result, tiny sparks create localized melting on the workpiece’s surface, causing material removal. The shape and size of the electrode determine the final shape and dimensions of the machined feature.

The power source is responsible for generating the electrical discharge between the electrode and the workpiece. It provides high-frequency pulses of electricity to create the spark that causes the material removal. The power source controls various parameters, such as the pulse duration, current, and voltage, which influence the material removal rate, surface finish, and accuracy of the machining process.

During the EDM process, the electrode, whether in the form of a solid tool or a wire, is guided by CNC (Computer Numerical Control) systems. The CNC system interprets the part’s CAD/CAM data and generates the appropriate toolpaths for the electrode to follow, ensuring precision and accuracy in the machining process.

All these components work together in electrical discharge machinery to achieve precise and intricate material removal. The power source provides the necessary electrical energy to create the sparks, which erode the workpiece material. The electrode, whether a shaped tool or a wire, is carefully controlled and guided by the CNC system to ensure the desired shape is accurately machined on the workpiece. By adjusting various parameters such as the electrode material, power settings, and CNC toolpaths, manufacturers can achieve high-quality results in electrical discharge machining for a wide range of applications across various industries.

Process Considerations

Before starting the EDM process, the design and material selection are crucial factors. The component’s design should consider the EDM capabilities and limitations, such as electrode accessibility and minimum feature sizes. Material selection plays a vital role as some materials, like conductive metals, are more suitable for EDM than others. Additionally, the workpiece’s shape, size, and fixturing need to be considered to ensure stability and accuracy during machining.

During the EDM process, factors such as the choice of electrode material, toolpath strategy, and flushing conditions are critical. The selection of the electrode material must match the workpiece material to achieve the desired results without causing excessive wear. Toolpath strategy involves determining the path the electrode will follow during machining, which affects the surface finish, accuracy, and efficiency of the process. Proper flushing is also essential to remove debris and maintain a stable spark gap, ensuring consistent material removal.

After the EDM process, inspection and post-processing play significant roles. Inspection is necessary to verify that the machined components meet the required specifications and tolerances. Post-processing operations like deburring, cleaning, and heat treatment may additionally be needed to remove sharp edges, residual materials, or improve the component’s mechanical properties.

Throughout the entire EDM process, factors such as machining parameters, power settings, and electrode wear need to be monitored and adjusted as necessary. Controlling the spark parameters, like pulse duration and current, influences material removal rates and surface finish. Monitoring electrode wear is crucial to maintain dimensional accuracy and to replace worn electrodes when necessary. Additionally, proper maintenance and care of the EDM machine are essential for consistent and reliable performance.

Overall, a comprehensive understanding of the material properties, appropriate machining parameters, electrode selection, and diligent monitoring throughout the process are all vital factors to achieve successful and high-quality electrical discharge machining results.

Variations and Similar Processes

Some of the many methods that manufacturers may use to complete EDM machining include conventional EDM (sinker EDM), wire EDM, small hole EDM, fast hole drilling EDM, and micro EDM.

Conventional EDM, also known as ram EDM, sinker EDM, or plunge EDM, is the oldest and one of the two most widely used forms of electrical discharge machining. Sinker EDM is the best process to employ for the creation of complex geometries.

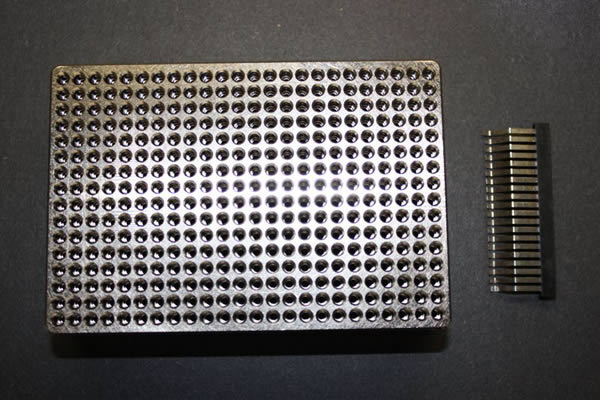

The sinker EDM method uses an electrode. The electrode is most often made out of machined graphite, though it may also be copper. The electrode plunges, or sinks, into metal to create complex 3D shapes, holes, and patterns.

Wire EDM, sometimes called wire erosion, is the other main type of electrical discharge machining. The wire EDM process, which can be quite efficient, works well for cutting shapes into both selected parts and entire assemblies. Wire EDM can also create recast layers. Instead of using an electrode, wire EDM uses a wire to transmit sparks to the work piece. This wire, which is made of a conductive material like brass, is fed from a spool through the work piece and then clamped on both ends by CNC-controlled diamond guides.

To create shapes and patterns, the wire cuts through the metal in a pattern. The pattern that the wire cuts is based on the movement of the arms of the CNC-operated guides. In order for wire EDM machining to take place, manufacturers must first put the part being cut most through the next process, small hole EDM.

Small hole EDM is a method of EDM drilling that creates holes and perforations. Manufacturers use it before wire EDM to create a hole through which the wire can be fed. In this way, it acts as an alternative to pre-drilling. Most often, manufacturers use small hole EDM to pass wire through parts and products like jet engines, turbine blades, spinnerets (tools designed to help with the extrusion of polymers into synthetic fibers), and fuel system parts.

Fast hole drilling EDM is a type of EDM machining that technicians use to quickly create small, deep holes in a workpiece. Usually, they can cut an inch-deep accurate hole in about one minute. Fast hole drilling EDM works using a rotating tube electrode that sprays a high pressure dielectric fluid jet. It is popular in drilling applications related to aerospace and energy.

Micro EDM is a process that treats extreme precision parts. Also known as μ EDM (μ is the symbol for microns), micro EDM creates erosions in nanoscale dimensions, and supplies a way to cut and tool parts that could not otherwise receive accurate treatment. Micro EDM processes work well for sensitive medical tools, optical tools, apertures, and the like.

Overseeing EDM

In the United States, the electrical discharge machining (EDM) process and the equipment used are subject to various regulations and standards to ensure safety, environmental compliance, and quality control. However, there isn’t a specific federal agency solely dedicated to overseeing EDM equipment or the process itself. Instead, EDM equipment is subject to broader regulations and standards that apply to machine tools and manufacturing processes.

For instance, the Occupational Safety and Health Administration (OSHA), a federal agency under the Department of Labor, is responsible for ensuring safe and healthy working conditions in the workplace. OSHA sets general machine guarding requirements and safety guidelines that apply to EDM machines to protect operators and workers from potential hazards.

Meanwhile, the National Institute for Occupational Safety and Health (NIOSH), another federal agency, conducts research and provides recommendations to prevent work-related injuries and illnesses. While not specifically focused on EDM, NIOSH’s guidelines and research can be relevant to improving safety and health in EDM facilities.

Additionally, there are industry-specific standards and certifications that EDM equipment manufacturers and users may follow voluntarily. For example, the American National Standards Institute (ANSI) publishes standards related to machine tool safety and performance, which can be applicable to EDM machines.

Furthermore, individual states may have their own regulations and environmental standards related to manufacturing processes, including EDM, which companies operating in those states must comply with.

It’s essential for manufacturers and users of EDM equipment to stay informed about relevant regulations, standards, and best practices to ensure compliance with safety, environmental, and quality requirements while operating electrical discharge machinery in the United States.

Benefits

Electrical discharge machining supplies a wide variety of advantages to both manufacturers and customers. First, electrical discharge machining creates products and parts with highly accurate markings, angles, cuts, etc. Second, EDM machines can machine even the smallest parts or smallest lines. The complex shapes that manufacturers can make with EDM tooling would be difficult or impossible with traditional tooling. In addition, all EDM machines can accurately cut even the hardest of metals without preheating them. The removal of this step in the machining process saves manufacturers both time and money.

Unlike many other machining methods, EDM does not use impact or abrasion to achieve its goals. In fact, the EDM tool never makes physical contact with the part being machined. This is a significant advantage. Because the EDM tool never makes physical contact with the part being machined, that part is not deformed, nor does it sustain heat damage or imperfections like burrs. Likewise, with EDM, manufacturers can machine excellent surface finish qualities the first time around.

Things to Consider

Before commissioning a company for electrical discharge machining services, you need to do your research. Because EDM creates such delicate and complex cuts and lines, you want to make sure the service provider making these cuts and lines is up to the task. You also want to make sure they have the right EDM equipment, adequate certification, and a solid track record to back them up.

The EDM market is flooded with service provider listings on the internet. Some are good, and some are not. To narrow down the field of candidates for you, and to make sure you end up with a high-quality service provider, we’ve put together a list of several EDM companies and contract manufacturers we trust. You will find that list, complete with links and profiles, in the middle of this page. We believe the best way to approach them is with your specifications in hand. Write out your specifications before you begin browsing, so that you can quickly make informed decisions concerning which manufacturers will or will not work well for you. Based on the services they offer, pick out three or four EDM suppliers to which you would like to speak, and reach out to them. Go over your application at length with each of them, then compare and contrast what they’ve offered. Decide which company is right for you and get started.

Aluminum Anodizing

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services