Electrical discharge machining , or EDM for short, is a highly accurate machining process during which sparks, or electrical discharges, shape a workpiece by removing material. Read More…

XACT Wire EDM Corp. is one of the largest and most experienced Wire EDM Companies in the country. Our Wire EDM manufacturing capabilities include a large number of high-end machines with two locations offering advanced CMM and video inspection. We work with a wide variety of customers in the medical, defense, aerospace, automation, robotics industries as well as many companies in the metal...

Twin City is ISO 9001:2000 certified for all simple & complex EDM services, in addition to many other services & their forte is producing difficult, complex parts through their state-of-the-art equipment & highly skilled staff. TC will perform the nearly impossible & is known to give both 100% in quality & service. Our flexibility & versatility provide customers with affordable convenience.

At Sematool Precision Mfg. Inc., we specialize in delivering high-precision EDM services that meet the exacting demands of modern manufacturing. Our expertise in both wire and sinker EDM allows us to produce complex geometries, tight tolerances, and fine finishes that conventional machining simply can’t achieve. We work closely with our clients to develop EDM solutions tailored to unique...

At Pivot Precision Corporation, we advance what’s possible in electrical discharge machining by pairing deep process expertise with a relentless commitment to accuracy, speed, and reliability. We focus on EDM because it lets us create features conventional cutting can’t reach—razor-sharp internal corners, fine slots, complex contours, and micro-scale details—without inducing mechanical...

Custom EDM is a leading company specializing in providing comprehensive Electrical Discharge Machining (EDM) solutions for a wide range of industries. With our extensive experience and expertise in EDM technology, we pride ourselves on delivering high-quality, precision-engineered products and services that meet the unique needs of our valued customers.

At The Damm Company, Inc., we take pride in being a trusted provider of precision machining solutions with a strong focus on Electrical Discharge Machining (EDM). Over the years, we have built our reputation through consistent performance, technical expertise, and a dedication to achieving the tightest tolerances for complex components.

More EDM Companies

Applications of EDM

Electrical discharge machining (EDM), sometimes referred to as spark erosion machining, is a cutting-edge manufacturing process highly valued for its unparalleled precision and versatility. EDM is widely used across numerous industries due to its capability to produce intricate and high-tolerance components that are challenging or impossible to achieve with traditional manufacturing methods.

Aerospace Industry: In the aerospace sector, EDM is essential for manufacturing critical engine and aircraft parts that require extreme precision, tight tolerances, and complex geometries. Components such as turbine blades, jet engine parts, fuel nozzles, and aerospace tooling rely on EDM for accurate shaping and finishing, which ensures optimal performance and safety. EDM’s non-contact process is crucial for handling superalloys and hard metals commonly used in aerospace engineering.

Automotive Manufacturing: The automotive industry leverages EDM for producing high-precision dies and molds used in the mass production of gears, transmission components, braking systems, engine parts, and detailed automotive molds. EDM’s ability to machine hardened steels and create detailed surface features makes it indispensable for both tool and die making and for prototyping advanced automotive parts.

Defense and Military Applications: In the defense industry, EDM is utilized to manufacture specialized components for military vehicles, weapons systems, and aircraft. Its precision ensures the accuracy and reliability required for mission-critical parts, such as fire-control systems, missile guidance components, and armor plating.

Extrusion and Tooling Industry: EDM is fundamental in the extrusion industry for producing precision molds and dies used in the shaping of plastics, metals, and composite materials. The ability to create complex profiles and intricate detail enables manufacturers to fabricate a vast array of custom extruded products for construction, transportation, and industrial applications.

Medical Device Manufacturing: In the medical field, EDM is extensively used to manufacture surgical tools, orthopedic implants, dental prosthetics, and micro-components. The precision offered by EDM ensures biocompatibility and exact fit, which are critical to patient safety and successful medical procedures. EDM is also key in producing minimally invasive surgical devices and microfluidic components.

Electronics and Semiconductor Industry: The electronics and semiconductor industry depends on EDM for creating microelectromechanical systems (MEMS), intricate connectors, lead frames, and molds for semiconductor packaging. EDM is capable of producing miniature, high-tolerance components essential for next-generation electronic devices.

Food and Beverage Manufacturing: The food and beverage industry benefits from EDM in the creation of specialized molds for chocolate, candy, and confectionery production. EDM’s precision enables the crafting of intricate and attractive designs that add value and uniqueness to consumer products.

Stamping and Sheet Metal Fabrication: EDM is widely used in the stamping industry to produce dies for sheet metal fabrication. Its ability to maintain accuracy and repeatability is essential for high-volume production of complex and detailed stamped parts used in household appliances, electronics, and industrial machinery.

Energy Sector: Power generation and energy industries utilize EDM for manufacturing turbine components, fuel injection parts, and nozzles that require precise internal geometries and superior surface finishes, especially in gas and steam turbines where high performance is essential.

Overall, electrical discharge machining is a transformative process that enables innovation and advanced manufacturing across multiple sectors. Its unique capabilities for producing complex, high-precision components are vital for advancing technology, enhancing product performance, improving manufacturing efficiency, and driving competitive advantage in today’s global markets.

Looking for industry-specific EDM solutions?

Explore our EDM company listings to find suppliers with expertise tailored to your sector, whether you need aerospace-grade components, automotive tooling, or custom medical device fabrication.

History of Electrical Discharge Machining

The development of electrical discharge machining (EDM) is rooted in centuries of scientific discovery and industrial innovation. The process traces its origins back to 1770, when Joseph Priestley, a renowned British scientist, observed that electrical discharges could cause localized erosion of materials—a phenomenon now recognized as electro-discharge erosion. While this observation laid the groundwork, it was not until the 20th century that EDM’s true potential was realized.

In the 1940s, Soviet researchers N.I. Lazarenko and B.R. Butinzky made breakthrough advancements in EDM technology. Through experiments involving tungsten electrical contacts and dielectric fluids, they discovered that immersing electrodes in an insulating fluid allowed for controlled erosion through sparking. This led to the development of the first resistor-capacitor circuit (RC circuit) EDM machines, which used controlled electrical pulses to shape hard-to-machine metals.

Simultaneously in the United States, a team of American scientists developed EDM machines capable of removing broken taps and drills from aluminum castings. These early machines featured robust sparking units, automatic spark repetition, electromagnetic interrupters, and innovative fluid replacement systems, achieving up to 60 sparks per second.

Subsequent improvements included the incorporation of vacuum tube circuits, which significantly increased spark rates and enabled the rapid production of die-cuts and molds. By the 1960s, engineers in both the United States and Soviet Union were competing to develop wire-cut EDM (also known as wire erosion), a process that uses a thin wire as an electrode to cut complex shapes in hardened steel and other materials.

The Soviets introduced the first commercially viable numerically controlled (NC) wire-cut EDM machine in 1967, laying the foundation for modern computer numerical control (CNC) EDM technology. In 1974, American researcher David H. Dulebohn and his team developed the first wire-cut EDM machine with CNC capabilities for plotting lines, and by 1976, this technology had evolved into fully CNC-controlled wire-cut EDM systems.

Throughout the 1970s and beyond, researchers sought to explain the underlying mechanisms of EDM. Notably, Frans Van Dijck’s 1973 doctoral thesis provided mathematical models for the process, while later research at Texas A&M University in 1989 offered empirical evidence supporting the theory of thermal material removal.

Today, EDM stands as a cornerstone of advanced manufacturing, with ongoing advances in materials science, machine control, and process optimization. Modern EDM machines enable manufacturers to achieve levels of precision, surface finish, and complexity that were once unimaginable, playing a vital role in electronics, aerospace, medical device manufacturing, and beyond.

Process Components and Operational Details

Electrical discharge machining (EDM) relies on a combination of advanced machinery, precise controls, and expert process management. The core components of an EDM system include the electrode (tool), power source, workpiece, dielectric fluid, and CNC control system. These elements work together to facilitate high-precision, non-contact material removal.

- Electrode (Tool): The electrode serves as the cutting tool in EDM. It is typically made from highly conductive materials such as graphite, copper, or tungsten. The electrode’s shape and size match the desired geometry to be imprinted on the workpiece. In sinker EDM, the electrode is machined to form a cavity; in wire EDM, a fine wire acts as the electrode.

- Power Source: An advanced power supply generates controlled, high-frequency electrical pulses between the electrode and the workpiece. These pulses create sparks that locally melt and vaporize the workpiece material, removing tiny amounts with each pulse. Adjustable parameters—such as pulse duration, current, and voltage—allow operators to fine-tune machining speed, surface finish, and feature accuracy.

- CNC Control System: Modern EDM machines are equipped with sophisticated CNC (computer numerical control) systems. The CNC interprets CAD/CAM data to generate precise toolpaths, ensuring the electrode (or wire) follows the programmed shape with micron-level accuracy. This automation is essential for producing repeatable, high-complexity parts.

- Dielectric Fluid: A dielectric fluid (often deionized water or synthetic oil) immerses the machining area, playing several crucial roles. It insulates the gap between the electrode and the workpiece, flushes away eroded particles, cools the work zone, and helps control the spark gap for consistent machining results.

- Workpiece: The workpiece is typically a conductive material, such as hardened tool steel, titanium, Inconel, aluminum, or carbide. The EDM process requires the workpiece to be electrically conductive to allow the passage of current and spark formation.

How does EDM achieve such high precision?

Each spark generated during the EDM process removes only a microscopic amount of material, resulting in extremely fine detail and precise control over feature size and geometry. The lack of mechanical force eliminates the risk of deformation, making EDM ideal for fragile or thin-walled components.

During setup, careful consideration is given to workpiece fixturing, electrode design, and selection of machining parameters. Throughout the operation, real-time monitoring of spark energy, electrode wear, and dielectric fluid quality ensures consistent, reliable results.

After machining, components are inspected for dimensional accuracy and surface finish, often using advanced metrology equipment such as coordinate measuring machines (CMMs) and surface profilometers. Post-processing steps, such as deburring, cleaning, and heat treatment, may be performed to enhance part performance and longevity.

Pre-Process Considerations and Process Optimization

Before starting the EDM process, manufacturers must carefully assess several variables to ensure optimal results. Key considerations include:

- Design for Manufacturability (DFM): The component’s design should account for EDM’s unique capabilities and limitations, such as minimum feature size, electrode accessibility, and achievable surface finish. Early collaboration with experienced EDM engineers can help avoid costly design changes later.

- Material Selection: Only electrically conductive materials can be machined with EDM. Common choices include tool steels, titanium, tungsten carbide, copper alloys, and superalloys. Each material responds differently to EDM, affecting machining speed, electrode wear, and surface integrity.

- Fixturing and Workholding: Secure, vibration-free fixturing is essential for maintaining accuracy, especially during long or complex EDM cycles. Custom fixtures may be required for odd-shaped or delicate parts.

- Electrode Material and Geometry: The choice of electrode material must match the workpiece’s properties and the desired machining outcome. For example, graphite electrodes are favored for their machinability and wear resistance, while copper is chosen for fine-detail work.

- Machining Parameters: Adjusting pulse duration, current, voltage, and flushing settings allows manufacturers to balance material removal rate, surface roughness, and electrode wear. Expert adjustment of these EDM parameters is crucial for process efficiency and part quality.

- Debris Removal and Flushing: Proper flushing of the dielectric fluid is necessary to clear eroded particles from the spark gap, prevent arcing, and maintain process stability.

- Post-Process Inspection: Dimensional verification, surface finish assessment, and quality control are vital to ensure that each part meets its specifications. Advanced metrology tools and non-destructive testing methods are often employed.

Continuous improvement in setup, monitoring, and maintenance of EDM machinery is key to reducing downtime, improving repeatability, and extending equipment lifespan.

Variations and Similar Processes in EDM

Manufacturers employ a range of EDM process variants to address diverse application requirements, part geometries, and production volumes. The primary types of electrical discharge machining are:

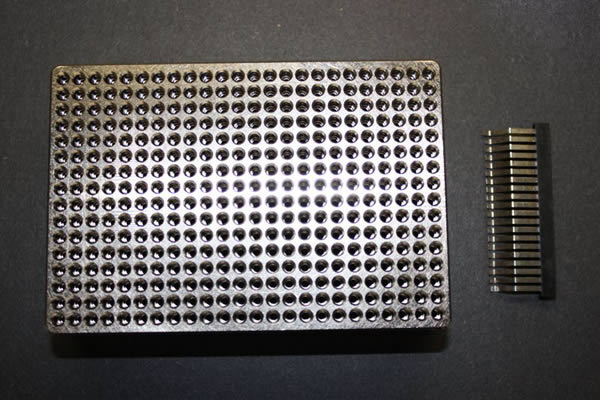

- Sinker EDM (Conventional EDM/Ram EDM/Plunge EDM): This is the most traditional and widely used EDM method. Sinker EDM uses a pre-machined electrode (typically graphite or copper) that is “sunk” into the workpiece to form intricate 3D cavities, holes, and undercuts. It excels at producing molds, dies, and complex internal features in hardened steels and alloys.

- Wire EDM (Wire Erosion): Wire EDM uses a continuously fed, tensioned wire (usually brass) as the cutting electrode. The wire moves in two axes, guided by CNC controls, to cut complex 2D and 3D profiles with exceptional accuracy. Wire EDM is ideal for producing punches, dies, extrusion dies, and intricate part shapes from thick plates or stacked materials. It can also create recast layers and intricate contours.

- Small Hole EDM (Hole Popping): Small hole EDM, or EDM drilling, creates deep, precise micro-holes in hard or delicate materials. It uses a rotating tube electrode and high-pressure dielectric flushing to rapidly produce holes as small as 0.1 mm in diameter. This technique is crucial for aerospace jet engine cooling holes, fuel injector nozzles, spinnerets, and other micro-feature applications.

- Fast Hole Drilling EDM: This is a rapid variant of small hole EDM, designed for high-speed drilling of deep, narrow holes (e.g., in turbine blades, medical devices, or energy sector components). It can penetrate an inch-deep in about a minute, making it ideal for production environments requiring speed and accuracy.

- Micro EDM (μ EDM): Micro EDM operates on the micron and sub-micron scale, producing extremely fine features and surface structures. It is indispensable for manufacturing micro-injection molds, precision medical instruments, microfluidic devices, and optical components. Micro EDM offers unmatched accuracy and can produce erosions at the nanoscale level.

EDM processes also share similarities with other non-traditional machining techniques, such as electrochemical machining (ECM) and laser machining. While EDM uses electrical discharges to erode conductive materials, ECM uses electrolytic dissolution, and laser machining relies on high-intensity light energy.

Regulatory Oversight and Industry Standards for EDM

The use of electrical discharge machining (EDM) in the United States is subject to a framework of regulations and standards that ensure workplace safety, environmental protection, and product quality. While there is no single federal agency dedicated exclusively to EDM, several regulatory bodies and industry organizations provide oversight and guidance.

- Occupational Safety and Health Administration (OSHA): OSHA sets forth general machine guarding requirements and safety standards for operating EDM machines. These rules are designed to protect operators from electrical hazards, moving parts, and accidental contact during the machining process.

- National Institute for Occupational Safety and Health (NIOSH): NIOSH conducts research and issues recommendations for improving workplace safety, including best practices for EDM facilities. While not EDM-specific, their guidelines contribute to safer machine operation and reduced risk of work-related injuries.

- American National Standards Institute (ANSI): ANSI publishes standards related to machine tool safety, performance, and design. These standards, often adopted by EDM machine manufacturers and users, help ensure consistent quality and reliability across the industry.

- State and Local Environmental Regulations: Many states have their own regulations governing waste disposal, chemical handling, and environmental protection related to EDM processes, particularly for managing dielectric fluids and eroded material waste.

- Industry Certifications: Manufacturers and EDM job shops may pursue voluntary certifications such as ISO 9001 (quality management), ISO 13485 (medical device manufacturing), or AS9100 (aerospace quality management) to demonstrate compliance with industry best practices and customer requirements.

It is essential for EDM equipment owners and operators to stay informed about evolving regulations and standards. Regular training, machine maintenance, and adherence to safety protocols are necessary for maintaining compliance, minimizing liability, and ensuring a safe, efficient manufacturing environment.

Benefits of Electrical Discharge Machining

Electrical discharge machining (EDM) provides a host of advantages, making it the preferred manufacturing process for many high-precision, high-value applications:

- Extreme Precision and Accuracy: EDM can routinely achieve tolerances within microns, making it ideal for intricate geometries, fine features, and tight-fitting assemblies.

- Ability to Machine Hard and Exotic Materials: Unlike traditional machining, EDM can cut through hardened steels, tungsten carbide, titanium, Inconel, and other superalloys—without the need for preheating or annealing.

- Non-Contact, Stress-Free Machining: The EDM tool never physically touches the workpiece, preventing mechanical stress, deformation, and tool-induced defects. This is critical for delicate, thin-walled, or heat-sensitive components.

- Complex 3D and Internal Features: EDM creates shapes and internal cavities that are impossible or highly impractical with conventional milling, turning, or drilling.

- Superior Surface Finish: EDM delivers excellent surface quality with minimal secondary finishing, reducing labor and material costs.

- No Burr Formation: As EDM is a non-abrasive process, it eliminates burrs, reducing post-processing time and improving part quality.

- Reduced Tool Wear and Maintenance: Since there is no cutting force or tool friction, EDM electrodes wear gradually and predictably, leading to lower tooling costs and longer machine uptime.

- Automation and Repeatability: CNC-controlled EDM machines enable automated, lights-out operation and consistent part-to-part repeatability—ideal for both prototype and high-volume production.

These benefits translate to faster project turnaround, lower production costs, and higher-quality end products, enhancing competitiveness and customer satisfaction.

Key Considerations When Choosing an EDM Service Provider

Selecting the right electrical discharge machining (EDM) partner is a critical decision that can directly impact project success, lead times, and overall manufacturing costs. Here are essential factors to guide your evaluation:

- Technical Capabilities: Assess whether the company offers the specific EDM processes you require (sinker EDM, wire EDM, micro EDM, small hole EDM) and can handle your material and tolerance needs.

- Equipment and Technology: Look for providers with state-of-the-art CNC EDM machines, automated tool changers, and advanced inspection systems. Modern equipment ensures higher precision, faster turnaround, and greater process flexibility.

- Certifications and Quality Systems: Verify that the EDM supplier maintains relevant certifications, such as ISO 9001, AS9100, or ISO 13485, to ensure adherence to industry-recognized quality standards.

- Experience and Track Record: Request references or case studies demonstrating the supplier’s expertise in your industry or similar projects. A proven track record in aerospace, medical, automotive, or defense manufacturing is a strong indicator of capability.

- Capacity and Lead Times: Evaluate the provider’s production capacity and typical lead times. Choose a partner that can meet your delivery schedules, especially for time-sensitive or high-volume orders.

- Customer Support and Communication: Effective communication and responsive engineering support are vital for project success. Choose a partner who collaborates openly and provides regular progress updates.

- Cost and Value: Obtain detailed quotes and compare not just price, but also value-added services such as design assistance, rapid prototyping, post-processing, and quality assurance.

To streamline your selection process, we have curated a list of trusted EDM companies and contract manufacturers. Prepare your project specifications and requirements beforehand to efficiently evaluate which providers best suit your needs.

How to Find the Right EDM Supplier:

- Identify three or four potential EDM suppliers based on their capabilities and reputation.

- Initiate contact and share your technical requirements, drawings, and performance expectations.

- Discuss your project thoroughly, ask for recommendations, and compare their proposals.

- Evaluate quality systems, turnaround times, and value-added services before making your final selection.

- Choose the EDM service provider that best meets your criteria and proceed with confidence.

Ready to start your next EDM project?

Browse our comprehensive EDM supplier directory to connect with industry-leading experts and request a quote today.

Conclusion: Unlock the Power of EDM for Advanced Manufacturing

Electrical discharge machining is more than just a fabrication technique—it is a cornerstone of modern manufacturing innovation. By enabling the production of highly complex, precise, and reliable components from the world’s hardest materials, EDM empowers manufacturers to meet the growing demands of aerospace, automotive, medical, electronics, defense, and energy industries. Whether you require intricate molds, high-precision medical devices, or custom tooling, EDM offers a versatile, cost-effective, and highly accurate solution.

If you are seeking reliable EDM services, advanced process guidance, or simply want to learn more about the capabilities of electrical discharge machining, explore our in-depth resources, connect with our curated network of expert EDM suppliers, or contact us directly for personalized advice.

What industries commonly use electrical discharge machining (EDM)?

EDM is used across aerospace, automotive, defense, extrusion and tooling, medical device manufacturing, electronics and semiconductor, food and beverage, stamping and sheet metal fabrication, and energy sectors for producing components requiring extreme precision and complex geometries.

What are the main benefits of EDM compared to traditional machining?

EDM offers extreme precision, the ability to machine hard and exotic materials, non-contact stress-free machining, production of complex 3D features, superior surface finish, no burr formation, reduced tool wear, and reliable, automated repeatability.

What are the primary types of EDM processes?

The main types of EDM are sinker EDM (also known as conventional or ram EDM), wire EDM (wire erosion), small hole EDM (hole popping), fast hole drilling EDM, and micro EDM (μ EDM). Each is suited for different part geometries, sizes, and levels of detail.

What materials can be machined using EDM?

EDM is suitable for electrically conductive materials, such as hardened tool steel, titanium, Inconel, carbide, aluminum, copper alloys, and superalloys. Non-conductive materials cannot be machined using EDM.

How does EDM achieve high precision and detail?

EDM uses controlled electrical sparks to remove microscopic amounts of material with each pulse, allowing for extremely fine detail and precise control of feature geometry, all without mechanical force that might deform delicate parts.

What should be considered when choosing an EDM service provider?

Key considerations include the provider’s technical capabilities, equipment and technology, certifications and quality systems, industry experience and track record, production capacity and lead times, customer support, and overall value including design assistance and post-processing services.

Are there regulatory standards for EDM in the United States?

Yes, EDM use is governed by workplace safety and product quality standards set by organizations like OSHA, NIOSH, and ANSI, as well as state and local environmental regulations. Voluntary industry certifications (e.g., ISO 9001, AS9100) may also apply to EDM service providers.

Aluminum Anodizing

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services