Hard materials are frequently machined using the non-conventional process known as electrical discharge machining (EDM). This technique is well-liked since EDM can work with all materials, regardless of how hard they are. Modern engineering materials used in harsh environments are frequently molded or created through the Electrical Discharge Method technique. However, this method has its shortcomings. Low material removal rates and substantial tool wear can frequently reduce the effectiveness of this kind of machining. Read More…

XACT Wire EDM Corp. is one of the largest and most experienced Wire EDM Companies in the country. Our Wire EDM manufacturing capabilities include a large number of high-end machines with two locations offering advanced CMM and video inspection. We work with a wide variety of customers in the medical, defense, aerospace, automation, robotics industries as well as many companies in the metal...

Twin City is ISO 9001:2000 certified for all simple & complex EDM services, in addition to many other services & their forte is producing difficult, complex parts through their state-of-the-art equipment & highly skilled staff. TC will perform the nearly impossible & is known to give both 100% in quality & service. Our flexibility & versatility provide customers with affordable convenience.

At Sematool Precision Mfg. Inc., we specialize in delivering high-precision EDM services that meet the exacting demands of modern manufacturing. Our expertise in both wire and sinker EDM allows us to produce complex geometries, tight tolerances, and fine finishes that conventional machining simply can’t achieve. We work closely with our clients to develop EDM solutions tailored to unique...

At Pivot Precision Corporation, we advance what’s possible in electrical discharge machining by pairing deep process expertise with a relentless commitment to accuracy, speed, and reliability. We focus on EDM because it lets us create features conventional cutting can’t reach—razor-sharp internal corners, fine slots, complex contours, and micro-scale details—without inducing mechanical...

Custom EDM is a leading company specializing in providing comprehensive Electrical Discharge Machining (EDM) solutions for a wide range of industries. With our extensive experience and expertise in EDM technology, we pride ourselves on delivering high-quality, precision-engineered products and services that meet the unique needs of our valued customers.

At The Damm Company, Inc., we take pride in being a trusted provider of precision machining solutions with a strong focus on Electrical Discharge Machining (EDM). Over the years, we have built our reputation through consistent performance, technical expertise, and a dedication to achieving the tightest tolerances for complex components.

More Electrical Discharge Machining Companies

Electrical Discharge Machining (EDM) is a highly versatile and advanced manufacturing process that utilizes electrical sparks to erode material from a workpiece, enabling the precision machining of complex and hard-to-machine components. As the demand for tighter tolerances, intricate geometries, and superior surface finishes has grown across industries such as aerospace, medical device manufacturing, automotive, and tooling, EDM has become an indispensable solution for manufacturers seeking to overcome the limitations of conventional machining methods.

This guide explores the working principles of EDM, the different EDM methods such as wire EDM, sinker EDM, and hole drilling EDM, key components of EDM systems, and the diverse applications and advantages of EDM technology. Whether you are researching how EDM can solve specific manufacturing challenges, comparing EDM companies, or evaluating which type of EDM is best suited for your project, this comprehensive resource will provide the insights needed to make informed decisions.

What Is Electrical Discharge Machining (EDM)?

Electrical Discharge Machining (EDM)—also known as spark machining, spark eroding, die sinking, or wire burning—is a non-traditional machining process that removes metal from conductive workpieces using rapid, repetitive electrical discharges (sparks) between an electrode and the workpiece, both immersed in a dielectric fluid. Unlike conventional machining processes (such as milling, turning, or grinding), EDM does not rely on physical contact or force between the tool and the workpiece, making it ideal for machining hard materials, intricate shapes, and delicate features that would be challenging or impossible with standard CNC machining.

Are you wondering how EDM compares to traditional machining for your specific component? Or are you trying to determine if your material is suitable for EDM? Continue reading for detailed explanations and practical guidance.

Working Principle of EDM

The working principle of electrical discharge machining is based on the controlled generation of electrical sparks between a tool (electrode) and the workpiece, both of which must be electrically conductive. These high-frequency sparks create localized, high-temperature zones—reaching up to 10,000°C—causing tiny amounts of material to melt, vaporize, and be flushed away by the dielectric fluid.

When an electric spark strikes a metal surface, it erodes and evaporates a minuscule portion of the material. This spark erosion is precisely controlled by advanced power supplies and servo mechanisms, ensuring the desired geometry, dimensional accuracy, and surface quality are achieved. The process proceeds in rapid, controlled pulses, with each discharge removing a tiny volume of material, allowing for the creation of highly accurate and repeatable features.

Because EDM machining relies on electrical conductivity, both the electrode and the workpiece must be made from conductive materials such as steel, titanium, copper, aluminum, carbide, or exotic alloys commonly used in high-performance applications.

Key Components of EDM Systems

Power Generator

The power generator is the heart of any EDM machine, supplying controlled electrical pulses to create the spark discharges between the electrode and the workpiece. The generator is typically connected to the negative terminal (tool/electrode), while the workpiece is attached to the positive terminal. The type and quality of the power generator directly impact machining speed, surface finish, and accuracy. Common power generator types include:

- Resistance-capacitance (RC) type generator (relaxation generator)

- Rotary type generator

- Electrical pulse generator

- EDM hybrid generator (for advanced, multi-process systems)

Looking to optimize your EDM process for speed or surface finish? Consider how power generator selection impacts your results, or reach out to multiple EDM companies for expert recommendations.

Workpiece

The workpiece is the material being machined. It is securely mounted in a dielectric container and connected to the positive terminal of the power supply. Only electrically conductive materials are suitable for EDM; this includes hardened steels, titanium alloys, carbides, Inconel, and other alloys used in demanding applications such as aerospace, medical devices, and precision tooling.

Fixture

A robust fixture holds the workpiece securely within the dielectric container, ensuring accurate positioning, repeatability, and vibration-free machining. High-precision fixtures are especially important in tight-tolerance EDM applications, including micro-machining and the production of intricate molds or dies.

Dielectric Medium

The dielectric medium is a critical element in the EDM process, acting as both an insulator and a flushing agent. Typically, low-viscosity hydrocarbon oils or deionized water are used, depending on the specific EDM method. The dielectric fluid serves multiple functions:

- Maintains electrical insulation between tool and workpiece until the spark is initiated

- Cools and flushes away eroded particles (debris) from the machining gap

- Shapes the spark discharge and influences surface finish

- Prevents secondary arcing, ensuring consistent machining conditions

During operation, the dielectric is rapidly ionized, forming a conductive plasma channel through which the spark passes. The resulting localized explosion vaporizes a minute volume of material, which is then rapidly cooled and solidified as spherical debris particles, swept away by the dielectric flow.

Curious about the best dielectric fluids for your EDM setup or how fluid parameters affect machining performance? Ask our experts or browse our directory of EDM fluid suppliers.

Types of EDM Methods

EDM technology encompasses several distinct machining methods, each optimized for specific applications, geometries, and material types. Understanding the differences helps you select the right solution for your needs.

Wire EDM (Wire-Cut EDM or Wire Electrical Discharge Machining)

Wire EDM—also known as wire erosion, wire cutting, or wire spark EDM—is a high-precision process that uses a continuously fed thin wire (typically brass or copper) as the moving electrode to cut through the workpiece. The wire follows a programmed path, enabling the production of intricate, two-dimensional (and some three-dimensional) shapes with exceptional accuracy and surface finish. Deionized water is commonly used as the dielectric fluid in wire EDM systems.

- Ideal for cutting complex shapes, contours, and internal profiles in hardened tool steels, dies, molds, and medical components

- Wire never touches the workpiece, eliminating tool wear issues common in conventional machining

- Capable of achieving tolerances as tight as ±0.002 mm and surface finishes better than 0.2 μm Ra

- Frequently used for cutting punch and die sets, extrusion dies, aerospace components, and precision gears

Considering wire EDM for your next project? Request a quote from leading wire EDM companies or explore typical applications and tolerances achieved with wire-cut EDM.

Sinker EDM (Die Sinking EDM, Conventional EDM, Ram EDM)

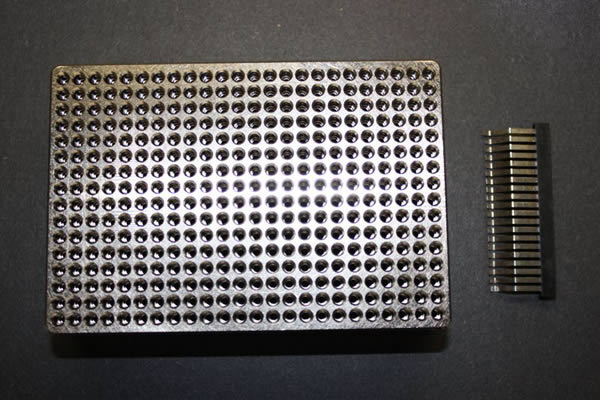

Sinker EDM—also called die sinking, sinking EDM, or ram EDM—employs a pre-shaped electrode (often made from copper, tungsten, or graphite) that is pressed into the workpiece to create complex cavities, undercuts, or negative forms. The shape of the electrode is mirrored in the machined cavity, enabling the production of dies, molds, and other intricate features.

- Best suited for forming cavities in hardened tool steels, mold steels, and carbides

- Electrode design is critical; copper electrodes offer superior surface finish and wear resistance, while graphite electrodes are easier to machine

- Widely used in injection mold production, die casting, stamping dies, and medical device tooling

- Capable of producing sharp internal corners, fine details, and deep cavities

Are you evaluating whether to use copper or graphite electrodes for your sinker EDM application? Learn more about electrode materials and their impact on EDM performance.

Hole Drilling EDM (EDM Drilling, Fast Hole EDM)

Hole EDM—sometimes referred to as small hole EDM, EDM drilling, or fast hole drilling—is a specialized method for creating extremely small and deep holes in conductive materials. Unlike conventional drilling, EDM drilling can produce holes as small as 0.1 mm in diameter with high aspect ratios, without the need for deburring or tool changes due to wear.

- Ideal for producing cooling holes in turbine blades, fuel injector nozzles, medical implants, and aerospace components

- Drills precise, burr-free holes in hardened alloys, carbides, and superalloys

- Enables rapid prototyping and high-volume production of micro-holes and features

- Capable of drilling through delicate or thin-walled workpieces without distortion

Want to compare small hole EDM providers or learn how EDM drilling outperforms conventional micro-drilling techniques? Explore our comprehensive guides and company directory.

Applications of EDM

EDM is widely recognized for its ability to machine difficult materials and produce geometries that are otherwise impossible using conventional methods. Key application areas include:

- Precision Machining: Manufacturing complex, high-precision parts for the aerospace, automotive, defense, and electronics industries.

- Injection Mold and Die Manufacturing: Creating intricate mold cavities, cores, and inserts for plastic, rubber, and metal injection molding.

- Die Casting: Machining hardened steel dies and dies for high-pressure casting applications.

- Small Hole Drilling: Fast, accurate, burr-free micro-hole production for turbine blades, fuel injectors, and medical devices. Find small hole EDM companies

- Aerospace & Defense: Cutting high-temperature alloys, producing cooling holes in turbine blades, and manufacturing mission-critical components.

- Medical Device Manufacturing: Machining surgical tools, implants, and micro-components from titanium, stainless steel, and cobalt-chrome alloys.

- Prototyping & Custom Tooling: Rapidly iterating complex geometries without the need for custom cutting tools or fixtures.

- Electronics and Semiconductor: Fabricating dies, lead frames, and micro-components with sub-micron tolerances.

- Automotive: Production of transmission parts, stamping dies, and high-performance engine components.

Advantages of EDM

EDM offers a range of significant benefits that make it a preferred choice for many advanced manufacturing and prototyping applications:

- Machines any hard material: EDM can process any electrically conductive material, including those that are heat-treated, alloyed, or exceptionally hard, such as tool steel, titanium, tungsten carbide, and Inconel.

- Produces intricate shapes: Complex geometries, undercuts, thin walls, and sharp internal corners can be machined with unmatched accuracy—ideal for injection molds, dies, and medical devices.

- High precision and accuracy: Achieves tolerances as fine as ±0.002 mm, making it suitable for micro-machining, precision tooling, and components with tight dimensional requirements.

- Superior surface finish: Achieves excellent surface finishes (down to 0.1–0.2 μm Ra) economically, reducing or eliminating the need for secondary finishing processes.

- No mechanical stress: As there is no direct contact between electrode and workpiece, EDM does not induce mechanical stresses, warping, or tool deflection—critical for delicate or thin-walled parts.

- Extends tool life: Proper cooling and lubrication of the electrode extend tool life, reducing operating costs in high-volume production.

- Repeatable and automated: EDM is highly repeatable and easily integrated into automated manufacturing cells, increasing throughput and consistency.

- Minimal burr formation: The process removes material by vaporization, virtually eliminating burrs and the need for post-machining deburring.

- Flexible for prototyping and production: Equally effective for single-part prototyping, low-volume runs, and mass production.

Looking for ways to reduce manufacturing costs or improve the quality of your finished parts? Discover how EDM can deliver a competitive edge in today's demanding manufacturing environment.

Limitations and Considerations of EDM

While EDM offers numerous advantages, it is important to be aware of its limitations and the factors that may influence process selection:

- Material conductivity: Only electrically conductive materials can be machined using EDM; non-conductive ceramics, plastics, or composites require alternative processes.

- Slower material removal rates: Compared to conventional milling or turning, EDM generally has a lower material removal rate, making it less suitable for large-volume stock removal.

- Electrode wear: In sinker EDM, the electrode gradually erodes and must be replaced periodically, especially when producing deep or complex cavities.

- Process cost: The need for specialized equipment, dielectric fluids, and consumables can increase operational costs, particularly for small production runs.

- Surface recast layer: A thin recast layer may form on the machined surface; in high-performance or fatigue-critical applications, this layer is often removed via polishing or secondary processes.

Want to know if EDM is cost-effective for your specific project or which type of EDM method best fits your application? Use our comparison guides or contact multiple EDM service providers for detailed quotes and technical advice.

Integrating EDM with Other Manufacturing Techniques

To overcome certain limitations and further enhance performance, EDM can be integrated with traditional and unconventional machining processes to form hybrid manufacturing systems. By combining EDM with CNC milling, grinding, laser machining, or additive manufacturing, manufacturers can achieve greater flexibility, improved surface quality, and enhanced productivity.

- Hybrid EDM-milling: Allows for roughing with CNC milling and finishing intricate features with EDM, optimizing cycle times and reducing tool wear.

- EDM-grinding combinations: Improve surface integrity, reduce recast layers, and increase dimensional accuracy in hard-to-machine materials.

- EDM-laser or EDM-ECM hybrids: Enable micro-structuring, surface texturing, or machining of multi-material components.

Are you exploring hybrid machining solutions to meet advanced manufacturing requirements? Dive deeper into hybrid EDM applications or reach out to our network of EDM service providers specializing in integrated manufacturing solutions.

Choosing the Right Electrical Discharge Machining Company

Selecting the best EDM service provider or EDM manufacturing partner is essential to achieving your quality, lead time, and cost objectives. Here’s how to streamline your search:

- Compare multiple EDM companies: Use our comprehensive EDM company directory to review business profiles, technical capabilities, certifications, and industry experience.

- Request quotes and project consultations: Each company profile features a contact form for direct communication. You can also use our simple RFQ (Request for Quote) form to contact several companies simultaneously, saving time and effort.

- Preview company capabilities: Our proprietary website previewer lets you quickly evaluate each provider’s specialties, technologies, and previous project examples before initiating contact.

- Evaluate decision factors: Consider lead times, pricing, quality certifications (such as ISO 9001 or AS9100), project management support, and previous customer reviews when making your decision.

Not sure which EDM supplier is right for you? Ask these questions when evaluating EDM companies:

- What types of EDM machining do you specialize in (wire EDM, sinker EDM, hole drilling)?

- What are your maximum and minimum achievable tolerances and part sizes?

- Which industries do you serve (aerospace, medical, automotive, etc.)?

- Do you offer additional value-added services (design support, surface finishing, assembly)?

- Can you accommodate prototyping as well as high-volume production?

Get started by browsing our curated list of EDM companies and submitting your project requirements for customized quotes.

Frequently Asked Questions About EDM

What materials are suitable for EDM?

EDM is effective for any electrically conductive material, including hardened steel, stainless steel, tungsten carbide, titanium, Inconel, aluminum alloys, copper, and exotic alloys used in high-temperature and high-strength applications.

How does EDM compare to CNC milling or laser cutting?

Unlike CNC milling, EDM can machine extremely hard materials and produce fine features without tool wear or mechanical stress. Compared to laser cutting, EDM achieves superior surface finishes and higher precision, especially in thick or multi-layered parts.

What is the typical lead time for EDM projects?

Lead times depend on part complexity, batch size, and provider workload, but EDM is often faster for intricate or hard-to-machine features due to the elimination of custom tooling and minimal post-processing.

Can EDM be automated for volume production?

Yes, modern EDM systems offer full automation, including robotic loading, in-process measurement, and integration with digital manufacturing systems for high-volume and lights-out production.

What industries use EDM the most?

EDM is widely used in aerospace, medical device manufacturing, automotive, tool and die, defense, electronics, and precision engineering sectors.

Still have questions? Contact our technical support team or submit your inquiry to connect with experienced EDM professionals.

Ready to Take the Next Step?

Whether you are designing a new product, improving existing tooling, or seeking precision machining services for challenging materials, Electrical Discharge Machining offers a powerful, reliable, and cost-effective solution.

Start your search for the ideal EDM company by browsing our directory, comparing capabilities, and requesting personalized quotes. Unlock new possibilities in manufacturing with the unmatched precision and versatility of EDM technology.

Aluminum Anodizing

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services