A non-conventional machining technique called electrical discharge machining (EDM), also known as spark eroding, spark machining, die sinking, wire erosion, or wire burning, removes electrically conductive materials using the thermal energy (melting and partial vaporization of the workpiece) produced by a series of sparks that occur between the electrode and workpiece. Materials with a range of hardness, complicated forms, strength, temperature resistance, fine surface smoothness, and precise dimensions may be machined effectively using the EDM method. The procedure relies on no physical touch between the tool and the work component. Read More…

XACT Wire EDM Corp. is one of the largest and most experienced Wire EDM Companies in the country. Our Wire EDM manufacturing capabilities include a large number of high-end machines with two locations offering advanced CMM and video inspection. We work with a wide variety of customers in the medical, defense, aerospace, automation, robotics industries as well as many companies in the metal...

Twin City is ISO 9001:2000 certified for all simple & complex EDM services, in addition to many other services & their forte is producing difficult, complex parts through their state-of-the-art equipment & highly skilled staff. TC will perform the nearly impossible & is known to give both 100% in quality & service. Our flexibility & versatility provide customers with affordable convenience.

At Sematool Precision Mfg. Inc., we specialize in delivering high-precision EDM services that meet the exacting demands of modern manufacturing. Our expertise in both wire and sinker EDM allows us to produce complex geometries, tight tolerances, and fine finishes that conventional machining simply can’t achieve. We work closely with our clients to develop EDM solutions tailored to unique...

At Pivot Precision Corporation, we advance what’s possible in electrical discharge machining by pairing deep process expertise with a relentless commitment to accuracy, speed, and reliability. We focus on EDM because it lets us create features conventional cutting can’t reach—razor-sharp internal corners, fine slots, complex contours, and micro-scale details—without inducing mechanical...

Custom EDM is a leading company specializing in providing comprehensive Electrical Discharge Machining (EDM) solutions for a wide range of industries. With our extensive experience and expertise in EDM technology, we pride ourselves on delivering high-quality, precision-engineered products and services that meet the unique needs of our valued customers.

At The Damm Company, Inc., we take pride in being a trusted provider of precision machining solutions with a strong focus on Electrical Discharge Machining (EDM). Over the years, we have built our reputation through consistent performance, technical expertise, and a dedication to achieving the tightest tolerances for complex components.

More EDM Machining Companies

Working Principles of EDM Machining

Electrical Discharge Machining (EDM), also known as spark erosion or spark machining, is a non-traditional machining process widely used in the manufacturing and metalworking industries for producing complex and precise components. In EDM, the workpiece is cut (eroded) using an electric spark as the cutting tool to create the finished item in the desired shape. This process allows for the accurate machining of electrically conductive materials, including hardened steel, titanium, carbide, and exotic alloys that are difficult or impossible to machine using conventional techniques such as milling, turning, or grinding. The underlying principle of EDM is based on the removal of material from a workpiece through a series of rapidly recurring electrical discharges (sparks) between two electrodes—one being the workpiece and the other the tool electrode—immersed in a dielectric fluid.

During the EDM process, electricity strikes the workpiece's points of least resistance, much like a lightning strike hitting a tree before it strikes the ground. This occurs as the electrical current travels through the electrode, typically as a square wave. The material is gradually removed from the workpiece through a series of controlled, rapidly repeated current discharges that occur between the two electrodes. These electrodes are separated by a dielectric liquid—often deionized water or a specialized oil—which acts as an insulator until the electrical field is strong enough to cause the dielectric to break down, resulting in a spark (electrical arc) that erodes the workpiece surface at a microscopic level.

The intensity of the electric field between the electrodes causes a rise in voltage, which triggers the breakdown of the dielectric fluid and the formation of a plasma channel. Meanwhile, the dielectric fluid serves additional purposes: it cools the work area, flushes away eroded particles (debris), and maintains a consistent gap between the tool and the workpiece called the "spark gap." The process is precisely controlled via computer numerical control (CNC) systems, ensuring extremely tight tolerances and highly repeatable results for intricate parts, molds, dies, and aerospace, automotive, or medical device components.

Curious about EDM Machining? Explore these common questions:

- What materials can be machined using EDM?

- How does EDM compare to CNC milling for precision parts?

- What industries benefit most from EDM technology?

- Is EDM suitable for prototype or high-volume manufacturing?

- What is the typical surface finish achievable with EDM?

Types of EDM Machining

There are several types of EDM machining processes, each optimized for specific applications and design requirements. The two primary types of EDM are:

- Die Sink EDM (also known as Ram EDM or Sinker EDM)

- Wire EDM (also called Wire-Cut EDM or Wire Erosion)

Die Sink EDM

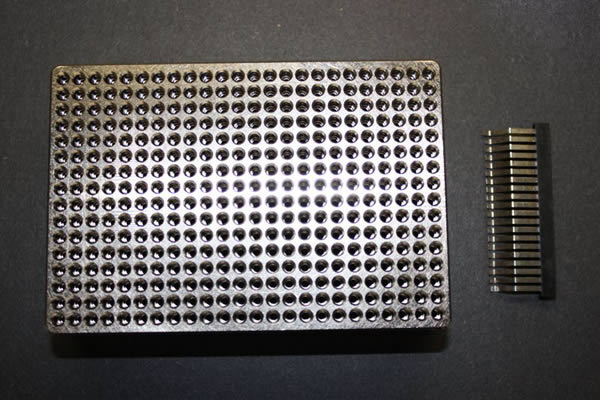

Die sinking EDM is a process in which the tool electrode and the workpiece are both submerged in a dielectric fluid, typically a light oil or deionized water, that continuously circulates to maintain optimal temperature and flush away particles. The tool electrode, often made of copper, graphite, or tungsten, is shaped to mirror the negative form of the desired cavity in the workpiece. As the electrode and the metal workpiece are brought close together, a high-voltage spark jumps across the narrow spark gap, eroding the workpiece precisely at the intended area. This technique is ideal for producing complex cavities, molds, dies, and intricate shapes that would be challenging or impossible to create with traditional tooling.

Die Sink EDM produces an even, continuous, high-quality surface finish with exceptional accuracy and repeatability. Unlike conventional machining processes, EDM does not apply cutting pressure to the workpiece, which is especially beneficial for delicate, thin-walled, or hard materials prone to deformation. The movement of the electrode is often controlled in a spiral or stepwise pattern, optimized by CNC programming, to achieve the desired surface texture. The dielectric fluid not only provides cooling and debris removal but also allows for static discharge and prevents oxidation of the machined surfaces.

Typical applications of Die Sink EDM include:

- Injection mold tooling and die sets for plastics, rubber, and metal casting industries

- Production of aerospace and automotive components with intricate geometries

- Manufacturing of medical device components, such as surgical instruments and implants

- Forming precise cavities, slots, and shapes in hard-to-machine materials

- Micro-machining for electronics and semiconductor industries

Key Decision Factors for Die Sink EDM

- Part complexity and geometry requirements

- Material hardness and conductivity

- Required tolerances and surface finish

- Production volume (prototyping vs. mass production)

- Lead time and cost considerations

Wire EDM

Wire EDM, also known as wire-cut EDM or wire erosion, utilizes a continuously fed thin wire as the electrode. This wire, typically made of brass, copper, or coated materials, is strung between two spools and kept under tension to ensure straight, precise cutting. The workpiece is submerged in a bath of deionized water, which acts as the dielectric fluid, providing insulation until the electrical field causes a spark to jump from the wire to the workpiece. As the electrically charged wire moves along a programmed path—controlled via advanced CNC systems—it cuts the workpiece through a series of rapid electrical discharges, producing extremely fine cuts and intricate profiles with remarkable accuracy.

Wire EDM is particularly well-suited for producing complex shapes, internal and external profiles, and fine details in hard or delicate materials. The process can cut workpieces with a thickness ranging from a fraction of a millimeter to several hundred millimeters, making it highly versatile. The upper and lower wire guides can move independently along the X, Y, U, and V axes, enabling the creation of tapered features (up to 30° or more) and 3D contours that are challenging for other machining technologies such as CNC turning or CNC milling to achieve.

Regular wire replacement and precise control over spark energy help maintain dimensional accuracy and surface integrity throughout the machining process. The deionized water not only cools the cutting area but also flushes away eroded particles and is continuously filtered and recirculated to maintain optimal performance and prevent contamination.

Common applications of Wire EDM include:

- Manufacturing precision components for the aerospace, automotive, and medical industries

- Cutting punch and die sets for stamping and forming operations

- Machining gears, splines, and intricate profiles in hardened materials

- Fabricating fine holes, slots, and contours in semiconductor and electronics components

- Rapid prototyping and low-volume production of custom parts

Key Questions When Selecting Wire EDM Services:

- What is the maximum workpiece thickness and material type your project requires?

- Does your application call for tight tolerances or ultra-fine features?

- Are you working with exotic alloys or materials that are difficult to machine?

- What is the required lead time for your parts?

- Need help with CAD/CAM design or file preparation for EDM?

Advantages of EDM Machining

EDM machining offers numerous advantages that make it a critical technology for modern manufacturing and precision engineering. The key benefits of EDM machining include:

- Ability to machine hard and exotic materials: EDM can easily cut hardened steel, carbide, titanium, Inconel, and other materials that are challenging for conventional machining methods.

- Creation of intricate and complex geometries: EDM is ideal for producing detailed shapes, sharp internal corners, and fine features that are otherwise impossible or costly to achieve.

- No mechanical contact: Since there is no direct contact between the tool and the workpiece, there is minimal risk of mechanical deformation or residual stresses, allowing for the machining of thin-walled, delicate, or fragile components.

- Excellent surface finishes: EDM processes can achieve smooth, high-quality surface finishes, often eliminating the need for secondary polishing or grinding operations.

- Tight tolerances and repeatability: EDM can routinely achieve tolerances in the micron range, making it the process of choice for industries that demand high precision, such as aerospace, medical, and electronics.

- Capability to machine very small or micro-holes: EDM can create holes with diameters as small as 0.1 mm (0.004")—ideal for filter screens, fuel injectors, and micro-components.

- Versatility for prototype and production: EDM is effective for both single-piece prototyping and high-volume manufacturing, with quick setup changes and minimal tooling requirements.

- Minimal tool wear for wire EDM: Since the cutting wire is continuously fed, there is less concern over tool wear, ensuring consistent quality throughout long production runs.

- Reduced fixture complexity: EDM requires simple fixturing, as clamping forces are low, and the process is not sensitive to vibration.

When Should You Choose EDM Machining?

- When machining hard materials or heat-treated parts

- For intricate or precise shapes with fine details

- When conventional machining fails to deliver required accuracies

- If minimal burrs and smooth surface finishes are critical

- When producing prototypes, one-offs, or custom parts on short timelines

- For applications in aerospace, medical, electronics, tool, and die industries

Disadvantages of EDM Machining

While EDM offers significant capabilities, there are also some limitations and challenges to consider when evaluating EDM for your manufacturing needs:

- Excessive tool wear (especially in die sink EDM): The electrode is consumed during machining and must be replaced or re-shaped frequently for consistent results.

- Fire risk from dielectric fluids: The use of oil-based dielectrics in some EDM machines may introduce fire hazards if not properly managed with adequate safety procedures.

- Requires skilled operators: EDM programming and setup are specialized skills, and experienced machinists are necessary to optimize process parameters and ensure quality output.

- Limited to electrically conductive materials: Non-conductive materials cannot be machined using conventional EDM; special setups or hybrid processes are required for such applications.

- Difficulty in replicating sharp edges: Electrode wear and spark overcut can lead to challenges in producing extremely sharp internal corners or fine features.

- Higher power consumption: EDM processes generally consume more energy than traditional machining methods, impacting operational costs.

- Higher cost for electrode fabrication: The time and expense involved in making custom electrodes for die sink (ram/sinker) EDM can add to project costs.

- Slower material removal rates: Compared to high-speed milling or turning, EDM is typically slower, especially for large-volume removal scenarios.

Considering EDM for Your Next Project? Ask Yourself:

- Does your part require features impossible to machine with traditional tools?

- Are the material and tolerance requirements best served by EDM?

- Is the lead time or cost justified by the benefits of precision and finish?

- Are safety measures in place to mitigate EDM-specific risks?

EDM Machining Applications and Industry Use Cases

EDM machining is integral to manufacturing sectors that demand high precision, complexity, and material versatility. Here are some typical industry applications and use case scenarios for EDM services:

- Aerospace: Turbine blades, fuel nozzles, and structural components in high-temperature alloys

- Medical Devices: Custom surgical tools, orthopedic implants, and microfluidic devices

- Automotive: Injection molds, dies, and high-precision gears or transmission components

- Tool and Die Making: Punches, dies, and forming tools with complex contours

- Electronics: Lead frames, connectors, micro-switches, and semiconductor components

- Defense: Specialty parts in armor-grade materials or exotic alloys

- Energy: Components for gas turbines, oil & gas exploration, and power generation

- Prototyping: Rapid development of functional prototypes with intricate features

Looking for EDM Machining Services?

- Compare local and national EDM job shops for your specific industry requirements

- Request quotes for wire EDM, sinker EDM, or hole drilling EDM services

- Ask about in-house design and engineering support for challenging projects

- Evaluate experience machining your required material types

- Inquire about inspection, quality control, and certifications (ISO, AS9100, etc.)

Choosing the Correct EDM Machining Company

Selecting the right EDM machining company is crucial for ensuring quality, on-time delivery, and cost-effectiveness in your manufacturing projects. To ensure you have the most positive outcome when selecting an EDM machining business, it is important to compare several EDM machining companies using our comprehensive directory of EDM machining companies. Each EDM machining company has a detailed business profile page highlighting their areas of experience, core capabilities, industries served, and unique value propositions. These profiles also include a convenient contact form for direct communication, allowing you to request more information, discuss project specifics, or obtain a tailored quote.

When evaluating potential EDM suppliers, consider the following:

- Technical expertise: Does the company have a proven track record with similar projects and materials?

- Equipment and technology: Are their EDM machines modern, well-maintained, and capable of meeting your precision and volume needs?

- Certifications and quality assurance: Does the supplier hold relevant certifications, such as ISO 9001, AS9100, or industry-specific qualifications?

- Turnaround time and flexibility: Can they accommodate your lead times, prototyping, or production schedule?

- Customer service and communication: How responsive and transparent are they in addressing your questions and concerns?

- Value-added services: Do they offer additional services such as CAD/CAM support, reverse engineering, or post-processing (deburring, polishing, inspection)?

- Pricing transparency: Are their quotes detailed and competitive, factoring in all aspects of the project?

Our directory makes it simple to review each EDM machining company website using our proprietary website previewer to learn what each company specializes in. Then, use our easy RFQ form to contact multiple businesses with the same request, streamlining your supplier evaluation process and helping you secure the best partner for your next EDM machining project.

Ready to Get Started?

- Search for local or specialized EDM machining providers by region or capability

- Contact multiple companies for custom quotes and capability comparisons

- Explore case studies and customer testimonials to validate supplier performance

- Ask about their support for prototyping, production, or R&D applications

For more information about sinker EDM, wire EDM, or to connect with leading EDM machining companies, explore our directory or reach out today for expert guidance on your next project.

Aluminum Anodizing

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services