Explore Our Electrical Discharge Machining Gallery

Welcome to our Electrical Discharge Machining Gallery! Click on the images below or use the menu above to explore top-tier EDM service providers and equipment manufacturers. These companies specialize in advanced spark erosion technologies used to machine complex parts with high precision and tight tolerances.

Overview of Electrical Discharge Machining

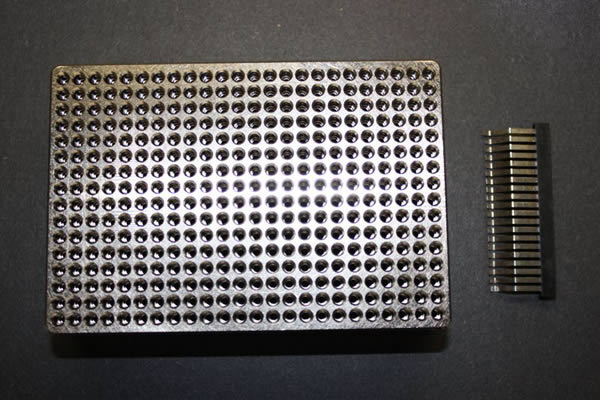

EDM is a non-contact machining process that removes material using controlled electrical sparks. This method excels at producing intricate shapes, tight radii, and fine features in hardened metals and alloys that are difficult to machine using traditional cutting methods.

Types of EDM and Their Applications

EDM includes sinker EDM, wire EDM, plunge EDM, and EDM drilling—each suited to specific geometries and tolerances. These technologies are ideal for tooling, mold making, aerospace components, medical device manufacturing, and other high-precision applications.

Industries Served by EDM Manufacturers

Industries such as defense, aerospace, automotive, electronics, and energy rely on EDM to achieve ultra-precise cuts in heat-treated or exotic materials. Whether it’s producing turbine blades or micro-components, EDM suppliers support mission-critical manufacturing needs.

Benefits of Choosing the Right EDM Supplier

Experienced EDM manufacturers offer not only advanced machinery but also engineering support for optimizing part geometry and minimizing cycle times. A trusted supplier helps deliver consistent accuracy, extended tool life, and production efficiency at scale.

Discover More Industry-Leading Suppliers

Need more options? Explore IQS Directory to find the most trusted manufacturers and suppliers in the industry.

Aluminum Anodizing

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services