Electrical discharge machining is often referred to as EDM, spark machining, spark eroding or die sinking and is one of the most accurate tooling methods available. Electrical discharge machines are increasing in popularity and are finding many applications in prototype production, stamping dies, small hole drilling and metal disintegration machining. They are most commonly used for producing the master dies, stamps and molds that will produce innumerous components for the automobile, aerospace, electronic and manufacturing industries. A wide range of materials can undergo EDM including aluminum, bronze, cobalt, copper, gold, iron, lead, nickel, silicon, silver, stainless steel, tin, tungsten, zinc and still others.

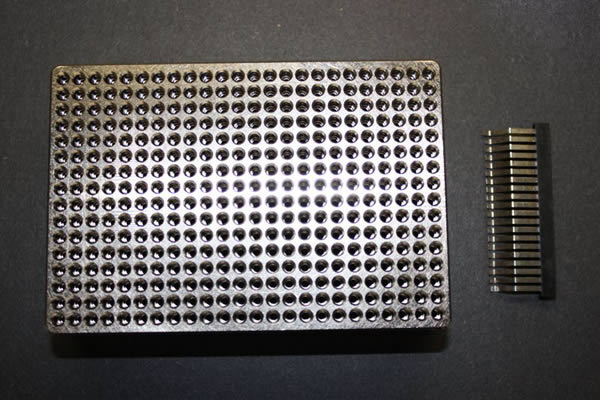

There are two main kinds of electrical discharge machining: sinker EDM, also known as plunge or ram, and wire EDM. Sinker electrical discharge machines are used to create a part from the raw materials where as wire electrical discharge machines use wire to cut shapes and details into the selected component. Either way offers precision and control because the electrode or wire moves through the metal without deforming the workpiece through heat damage and without crushing force.

Though there are many advantages to EDM, a standout example is that electrical discharge machining can create very complex designs for intricate parts, even on very small workpieces. Micro EDM is especially useful for electronics or handheld instruments. CNC EDM is the most precise of all because the machining is performed by computer controlled robots that complete automated, pre programmed movements. Electrical discharge machining is a valuable technology that greatly benefits the manufacturing and fabrication industries. It offers efficient and precise cutting, drilling and machining with little mechanical effort.

Aluminum Anodizing

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services