Many different terms, including ram EDM, cavity EDM, volume EDM, and conventional EDM, refer to sinker EDM. Spark erosion is used in sinker EDM, a subtractive manufacturing technique, to create extremely precise parts. Spark erosion is the hollowing out of metal workpieces using an electrode-shaped tool. The electrode sinks into the raw material, giving sinker EDM its name. Machines that operate horizontally or at any other angle are also a possibility. Read More…

XACT Wire EDM Corp. is one of the largest and most experienced Wire EDM Companies in the country. Our Wire EDM manufacturing capabilities include a large number of high-end machines with two locations offering advanced CMM and video inspection. We work with a wide variety of customers in the medical, defense, aerospace, automation, robotics industries as well as many companies in the metal...

Twin City is ISO 9001:2000 certified for all simple & complex EDM services, in addition to many other services & their forte is producing difficult, complex parts through their state-of-the-art equipment & highly skilled staff. TC will perform the nearly impossible & is known to give both 100% in quality & service. Our flexibility & versatility provide customers with affordable convenience.

At Sematool Precision Mfg. Inc., we specialize in delivering high-precision EDM services that meet the exacting demands of modern manufacturing. Our expertise in both wire and sinker EDM allows us to produce complex geometries, tight tolerances, and fine finishes that conventional machining simply can’t achieve. We work closely with our clients to develop EDM solutions tailored to unique...

At Pivot Precision Corporation, we advance what’s possible in electrical discharge machining by pairing deep process expertise with a relentless commitment to accuracy, speed, and reliability. We focus on EDM because it lets us create features conventional cutting can’t reach—razor-sharp internal corners, fine slots, complex contours, and micro-scale details—without inducing mechanical...

Custom EDM is a leading company specializing in providing comprehensive Electrical Discharge Machining (EDM) solutions for a wide range of industries. With our extensive experience and expertise in EDM technology, we pride ourselves on delivering high-quality, precision-engineered products and services that meet the unique needs of our valued customers.

At The Damm Company, Inc., we take pride in being a trusted provider of precision machining solutions with a strong focus on Electrical Discharge Machining (EDM). Over the years, we have built our reputation through consistent performance, technical expertise, and a dedication to achieving the tightest tolerances for complex components.

More Sinker EDM Companies

Sinker EDM: Comprehensive Guide to Electrical Discharge Machining for Precision Manufacturing

Sinker EDM, also known as ram EDM or cavity-type EDM, is a highly specialized electrical discharge machining process utilized for producing complex, high-precision, and intricate shapes in conductive materials. This advanced machining technology is a staple in modern manufacturing environments, especially where traditional machining methods reach their limits. Sinker EDM is essential for applications requiring superior accuracy, fine surface finishes, and the ability to machine difficult-to-reach features such as deep cavities, sharp internal corners, and delicate ribs. Explore our in-depth guide below to learn how sinker EDM works, its applications, material compatibility, decision factors, and how to choose the best sinker EDM provider for your needs.

What Is Sinker EDM and How Does It Work?

The sink in sinker EDM refers to the process by which a specially shaped tool-electrode (typically called the "electrode") is brought toward the workpiece-electrode (the "workpiece") until they nearly touch. A precisely controlled, high-voltage spark—also known as an EDM pulse—jumps across the tiny gap, melting and vaporizing minute amounts of material from the workpiece. This spark erosion process is repeated countless times per second, ultimately forming the desired cavity or feature in the metal. Sinker EDM is particularly effective for forming blind voids, slots, and intricate details in conductive metals and alloys.

During sinker EDM machining:

- The electrode and workpiece are submerged in a dielectric fluid (usually oil or deionized water), which prevents debris from adhering to surfaces and ensures a stable spark gap.

- Pulsed direct current is supplied between the electrode and workpiece, with both components being alternately charged.

- When the electrode approaches the workpiece, a spark forms, generating localized temperatures between 8,000 and 12,000°C—high enough to melt and vaporize metal instantly.

- Material is removed from the workpiece with each pulse, while the dielectric fluid flushes away particles and cools the area.

- The final result is a precisely machined cavity or feature, mirroring the electrode's geometry.

Unlike traditional CNC milling or turning, sink EDM machining is a non-contact, non-traditional process. This means:

- No mechanical cutting forces are applied, so delicate features aren’t distorted or damaged.

- Only electrically conductive materials can be machined, such as tool steel, titanium, carbide, Inconel, copper alloys, and exotic metals.

- The workpiece's hardness does not affect machinability—making EDM ideal for hardened tool steels and superalloys.

Core Components and Terminology in Sinker EDM

To better understand the sink EDM process, it's helpful to know the main system components and terminology:

- Electrode (Tool): The custom-shaped piece, usually copper, graphite, or an alloy, that forms the negative of the desired cavity.

- Workpiece: The target part, made from a conductive metal or alloy, to be machined.

- Dielectric Fluid: A non-conductive fluid (often hydrocarbon oil or deionized water) used to control sparking, flush debris, and cool the machining zone.

- EDM Pulse Generator: The power source that creates the rapid, high-voltage electrical pulses needed for spark erosion.

- Servo System: A precision control mechanism that manages the distance between the electrode and workpiece, maintaining the optimal spark gap throughout the process.

What Materials Can Be Machined with Sinker EDM?

Sinker EDM is renowned for its flexibility in machining a wide variety of conductive materials, regardless of their hardness or strength. This versatility makes it the preferred choice for industries requiring high-precision components, such as aerospace, medical device manufacturing, automotive, and injection molding. Common EDM-compatible metals include:

- Tool steels (H13, D2, A2, S7, etc.)

- Tungsten carbide

- Hardened steels

- Stainless steels

- Titanium and titanium alloys

- Inconel and other nickel-based superalloys

- Copper and copper alloys (including brass and tellurium copper)

- Aluminum alloys (when high accuracy is required)

- Exotic metals used in defense and aerospace

Have a specific material in mind? Contact our sinker EDM experts to discuss your project requirements or request a quote for your unique application.

Types of Sinker EDM Electrode Materials and Their Selection Criteria

Electrode selection is a critical decision in EDM machining, as the choice impacts accuracy, surface finish, tool wear, and manufacturing costs. Selecting the right EDM electrode material depends on the workpiece material, feature complexity, surface finish, and cost considerations. Here are the most commonly used electrode materials:

- Copper: Offers high electrical conductivity and produces fine finishes, making it ideal for intricate detail work and machining hard alloys like tungsten carbide.

- Copper Tungsten: Combines the conductivity of copper with the strength and temperature resistance of tungsten. Excellent for deep cavity machining and when flushing efficiency is a concern.

- Graphite: Lightweight, easy to machine, and highly resistant to wear, graphite is preferred for high-speed roughing and finishing operations. It is also less expensive for large electrode production.

- Silver Tungsten: Delivers superior conductivity and erosion resistance, making it suitable for high-power, high-precision EDM applications where anti-welding properties are essential.

- Brass: A cost-effective option, brass electrodes are easy to machine and often used for less demanding applications or mass production of similar cavities.

- Tellurium Copper: Blends machinability with conductivity, enabling the creation of intricate details and excellent surface finishes. Its machinability is close to that of brass, but it offers better electrical performance.

- Molybdenum: With high tensile strength and excellent conductivity, molybdenum is primarily used for wire EDM but also finds application in small diameter, high-precision sinker EDM work.

When choosing a sink EDM electrode, consider factors such as:

- Required surface finish quality and geometry complexity

- Workpiece material hardness and thermal conductivity

- Production volume and electrode manufacturing costs

- Tool wear resistance and expected material removal rate

- EDM process speed and overall project timeline

Still unsure about the best electrode for your application? Ask our technical team for recommendations based on your material, geometry, and finish requirements.

Applications of Sinker EDM: Where Is Sinker EDM Used?

Sinker EDM is widely adopted in industries that demand exceptional precision, repeatability, and the ability to produce features that would be impossible or prohibitively expensive to manufacture using traditional methods. Typical sinker EDM applications include:

- Mold making: Creating complex cavities, fine details, and textured surfaces for plastic injection molding, die casting, and rubber tooling.

- Die manufacturing: Producing stamping dies, extrusion dies, and forging dies with intricate geometries and high surface quality.

- Sharp inside corners and deep/thin ribs: Machining features that are difficult or impossible with rotary cutting tools.

- Blind cavities and keyways: Forming non-through holes, undercuts, or unusual shapes (such as hexagonal or spline forms) inside parts.

- Internal threads and splines: Generating precise internal features in hardened metals.

- Rapid Tooling: Quickly producing prototype or short-run tooling with complex features.

- Medical and aerospace components: Manufacturing miniature, high-precision parts from exotic alloys or difficult-to-machine materials.

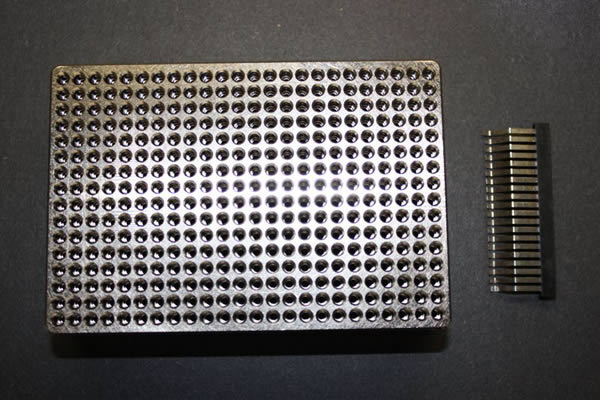

- Micro EDM: Creating extremely small holes, slots, and intricate patterns in micro-manufacturing applications.

Wondering if sinker EDM is right for your project? Request a feasibility analysis from our team or explore case studies on how sinker EDM has been used to solve challenging manufacturing problems.

Advantages of Sinker EDM in Precision Manufacturing

Sinker EDM offers several key advantages over conventional machining techniques, making it indispensable for high-precision applications:

- Unmatched accuracy: When paired with precisely machined electrodes, sinker EDM achieves tight tolerances and consistent repeatability, even on complex geometries.

- Blind cavity formation: Enables the creation of cavities, holes, and features with unique or undercut shapes, such as hexagons, splines, and non-circular profiles.

- Superior surface finish: Sinker EDM can achieve mirror-like surface finishes, reducing the need for secondary finishing operations.

- Tool material flexibility: The electrode does not need to be harder than the workpiece, allowing for cost-effective electrode production.

- No mechanical stress: The non-contact process eliminates stress, deformation, or burring on finished parts—crucial for delicate or thin-walled features.

- Work hardness independence: Sinker EDM can machine materials regardless of their hardness, enabling post-heat-treatment machining and reducing overall production steps.

- Reproducibility: Automated control systems and programmable EDM parameters ensure consistent quality for small-batch, large-lot, or one-off production runs.

- Micro-manufacturing capabilities: Sinker EDM is ideal for producing micro-features, miniature molds, and components for electronics, medical, and aerospace industries.

Disadvantages and Limitations of Sinker EDM

Despite its many strengths, sinker EDM is not suitable for every application. Understanding the limitations helps buyers and engineers make informed decisions:

- Slower material removal rate: Compared to high-speed CNC milling, EDM processes are generally slower and best suited for features where precision outweighs speed.

- Higher operating costs: Sinker EDM machines require significant electrical power, and costs can add up due to electrode manufacturing, dielectric fluid, and skilled labor.

- Material restrictions: Only electrically conductive materials can be machined; non-conductive materials like plastics, ceramics, or composites are not suitable for sinker EDM.

- Electrode wear: Electrode consumption can impact accuracy and increase consumable costs, especially for large or complex jobs.

- Maintenance requirements: Dielectric fluid management, filtration, and machine calibration demand regular attention to maintain process stability and part quality.

- Surface recast layer: The process creates a superficial "recast" or heat-affected layer that may require post-processing for certain high-performance or fatigue-critical components.

Need help deciding if sinker EDM or another machining process is best for your needs? Compare EDM vs. CNC milling, turning, and other processes with our expert guides.

Comparing Sinker EDM to Other EDM Processes: Sinker vs. Wire EDM

When researching EDM machining options, buyers often compare sinker EDM to wire EDM. While both use spark erosion, they serve different purposes:

- Sinker EDM utilizes a custom-shaped electrode to create 3D cavities, undercuts, and detailed features inside parts. It is ideal for mold making, die creation, and internal geometry machining.

- Wire EDM uses a continuously fed thin wire to cut through conductive material, producing through-cuts, intricate profiles, and fine details primarily in 2D or prismatic shapes.

Still weighing your options? Ask about which EDM process fits your application, material, and geometry requirements.

Factors to Consider When Choosing a Sinker EDM Service Provider

Finding the right sinker EDM company is crucial for project success, especially when dealing with tight tolerances, complex geometries, or mission-critical applications. Here are key decision factors to evaluate:

- Industry experience and specialization: Does the provider have a proven track record in your sector (aerospace, automotive, medical, tooling, etc.)?

- Machine capabilities: What are the size, accuracy, and feature complexity limits of their EDM equipment?

- Quality assurance and certifications: Are they ISO-certified or compliant with relevant industry standards?

- Lead time and capacity: Can they meet your turnaround time and production volume needs?

- Engineering support: Do they offer design for manufacturability (DFM) guidance, rapid prototyping, or project consultation?

- Customer reviews and project portfolio: What do other clients say about their performance, communication, and results?

Start your search by browsing our directory of sinker EDM companies. Each company profile details their areas of expertise, certifications, capabilities, and includes a direct contact form for RFQs or project inquiries. Use our patented website previewer to compare providers at a glance, then submit your project requirements through our unified RFQ form to receive competitive quotes from multiple qualified vendors.

Frequently Asked Questions About Sinker EDM

What industries benefit most from sinker EDM?

Sinker EDM is integral to industries such as aerospace, mold and die making, medical device manufacturing, automotive, defense, electronics, and energy. Any field requiring high-precision components from hard or exotic metals leverages sinker EDM for its accuracy and flexibility.

How does surface finish quality compare to other machining processes?

Sinker EDM can achieve surface finishes as fine as Ra 0.1–0.2 microns, comparable to or better than grinding and polishing. The finish depends on electrode material, pulse settings, and flushing techniques.

Can sinker EDM be combined with other manufacturing processes?

Yes, EDM is often used as a secondary or finishing process after conventional machining, forming, or additive manufacturing. It’s ideal for adding detailed features, texturing, or finishing hardened parts.

What is the typical lead time for sinker EDM projects?

Lead times vary by project complexity, electrode manufacturing, and provider capacity. Simple jobs may take a few days, while complex molds or production tooling could require several weeks. Rapid prototyping options are available from select providers.

How can I get a quote or consultation for my sinker EDM project?

Use our RFQ form or company directory to contact multiple reputable EDM service providers for quotes, capability assessments, and application engineering support.

Get Started with Sinker EDM: Request a Quote or Consultation

Ready to take the next step? Whether you’re sourcing precision sinker EDM services for prototyping, production, or toolmaking, our resources connect you to industry-leading providers with the expertise and technology to deliver exceptional results. Browse our directory to compare top-rated EDM companies, or request a custom quote tailored to your project’s requirements. Need advice? Our technical team is here to help you select the optimal machining process, electrode material, and surface finish for your application.

For additional information, technical resources, or to discuss your unique project challenges, contact our experts today.

Aluminum Anodizing

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services