Small hole EDM services are used in industries including automotive, injection molding, tool and die, medical and appliance with a wide variety of applications such as removing broken drill bits, small hole placement, hardened punch ejector holes and aircraft cooling holes. Read More…

XACT Wire EDM Corp. is one of the largest and most experienced Wire EDM Companies in the country. Our Wire EDM manufacturing capabilities include a large number of high-end machines with two locations offering advanced CMM and video inspection. We work with a wide variety of customers in the medical, defense, aerospace, automation, robotics industries as well as many companies in the metal...

Twin City is ISO 9001:2000 certified for all simple & complex EDM services, in addition to many other services & their forte is producing difficult, complex parts through their state-of-the-art equipment & highly skilled staff. TC will perform the nearly impossible & is known to give both 100% in quality & service. Our flexibility & versatility provide customers with affordable convenience.

At Wire Pro EDM Technologies, we specialize in delivering high-precision electrical discharge machining solutions that meet the rigorous demands of modern manufacturing. Our team is driven by a deep understanding of EDM technology and a passion for solving complex machining challenges with accuracy, consistency, and speed.

At Quality EDM, Inc., we specialize in delivering precise and reliable Electrical Discharge Machining solutions that meet the most demanding specifications across a wide range of industries. As a team of experienced professionals, we pride ourselves on our deep technical knowledge and our commitment to producing high-precision parts with exceptional consistency.

At Billet Industries, we specialize in delivering precision-engineered components with a strong focus on quality, reliability, and customer satisfaction. As a trusted partner in the manufacturing industry, we bring decades of experience to every project, combining advanced technologies with skilled craftsmanship to produce high-performance parts that meet the most demanding specifications.

Since 1981, King Tek EDM and Precision Machining has grown into a full-service machine shop capable of producing parts in there entirety. Our primary focus is electrical discharge machinery as we offer wire EDM, sinker EDM, and small hole EDM. Utilizing the latest wire machining technology, we are involved in new applications of a variety of industries outside tool and die like aerospace.

More Small Hole EDM Companies

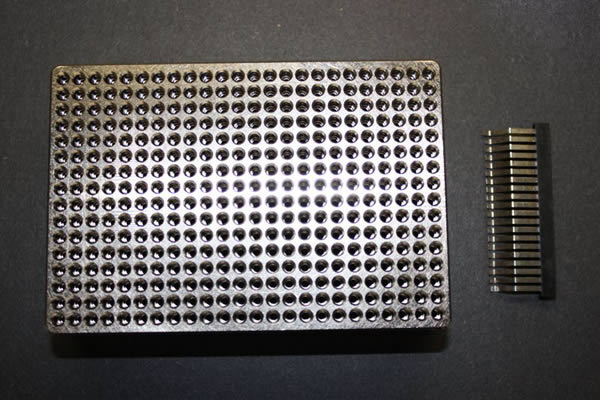

Small hole EDM, also known as fast hole drilling and start hole drilling, is a specialized tooling method that uses electrical energy to erode materials and produce holes in metals or parts which require close precision machining and repeatability. Small hole EDM drilling employs a round, hollow electrode that rotates around a spindle, similar to a drill and drill bit. A generator or power source electrically charges the electrode which then produces sparks or discharges, hence the term electrical discharge machining.

The sparks erode the surface of the work piece by creating microscopic pockets that eventually create a small hole. The work piece is also attached to a power source and placed in a water-based dielectric fluid. As the electrode and the work piece are brought closer together, an intense electric field is created which serves to erode away the material of the work piece. The dielectric fluid is responsible not only for conducting electricity during the process but also for maintaining the temperature and flushing away the unwanted material debris.

Small hole EDM services are used in industries including automotive, injection molding, tool and die, medical and appliance with a wide variety of applications such as removing broken drill bits, small hole placement, hardened punch ejector holes and aircraft cooling holes.

The process of small hole drilling can be used as an independent drilling process on specifically designed work pieces, or to make a through hole as a pretreatment for wire EDM which requires a hole to start the cutting process. Small hole drilling capabilities extend from .03mm to 6.1 mm holes and some can drill through 100 mm of soft or hard materials in less than ten seconds.

CNC EDM machines are used to control the depth and location of the holes during the electrical discharge machining process, as well as CAD and CAM software to instruct the path of the electrode/s. The size of the hole created is controlled by the diameter of the electrode. Small hole EDM can be used for any hard or soft electrically conductive materials, which include stainless steel, titanium, aluminum, copper, carbide and hard tool steels.

Some advantages that come with using small hole drilling services include the ability to drill on curved or angled surfaces, to drill through extremely hard or extremely delicate materials and to drill very deep holes, while remaining a fast, accurate and affordable process. However, there are some drawbacks to using small hole EDM which include a much longer drilling time for large holes compared to conventional drilling, an inability to control blind hole depth and significant electrode wear.

Aluminum Anodizing

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services