The electrothermal production process called wire EDM (Electrical Discharge Machining) uses a thin, single-strand metal wire and de-ionized water to cut through metal while preventing rust. Since the wire and the workpiece are not in direct contact during the wire-cutting process, the material’s shape and the wire’s course can be machined without being altered. Read More…

XACT Wire EDM Corp. is one of the largest and most experienced Wire EDM Companies in the country. Our Wire EDM manufacturing capabilities include a large number of high-end machines with two locations offering advanced CMM and video inspection. We work with a wide variety of customers in the medical, defense, aerospace, automation, robotics industries as well as many companies in the metal...

Twin City is ISO 9001:2000 certified for all simple & complex EDM services, in addition to many other services & their forte is producing difficult, complex parts through their state-of-the-art equipment & highly skilled staff. TC will perform the nearly impossible & is known to give both 100% in quality & service. Our flexibility & versatility provide customers with affordable convenience.

At Sematool Precision Mfg. Inc., we specialize in delivering high-precision EDM services that meet the exacting demands of modern manufacturing. Our expertise in both wire and sinker EDM allows us to produce complex geometries, tight tolerances, and fine finishes that conventional machining simply can’t achieve. We work closely with our clients to develop EDM solutions tailored to unique...

At Pivot Precision Corporation, we advance what’s possible in electrical discharge machining by pairing deep process expertise with a relentless commitment to accuracy, speed, and reliability. We focus on EDM because it lets us create features conventional cutting can’t reach—razor-sharp internal corners, fine slots, complex contours, and micro-scale details—without inducing mechanical...

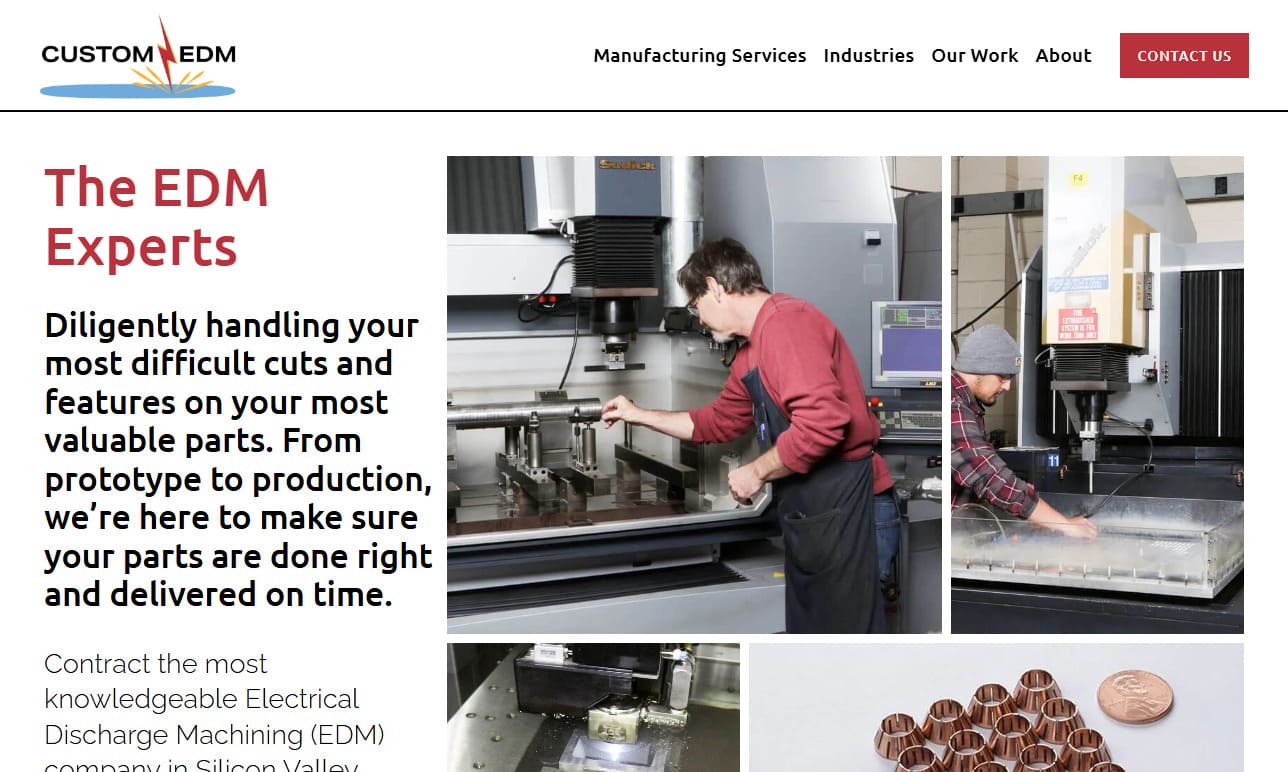

Custom EDM is a leading company specializing in providing comprehensive Electrical Discharge Machining (EDM) solutions for a wide range of industries. With our extensive experience and expertise in EDM technology, we pride ourselves on delivering high-quality, precision-engineered products and services that meet the unique needs of our valued customers.

At The Damm Company, Inc., we take pride in being a trusted provider of precision machining solutions with a strong focus on Electrical Discharge Machining (EDM). Over the years, we have built our reputation through consistent performance, technical expertise, and a dedication to achieving the tightest tolerances for complex components.

More Wire EDM Companies

Wire EDM (Electrical Discharge Machining) is a high-precision manufacturing process that uses a thin, electrically charged wire as an electrode to cut or shape conductive materials. The wire is rapidly charged to the desired voltage, initiating a controlled electrical discharge that erodes the workpiece at the point of contact. The wire is continuously surrounded by de-ionized water, which acts as a dielectric fluid. This fluid serves multiple functions: it cools the workpiece, flushes away microscopic particles generated during cutting, and prevents electrical arcing outside the gap. As a result, the hardness of the material being machined does not adversely affect the cutting speed, making wire EDM an excellent choice for processing extremely tough or hardened metals.

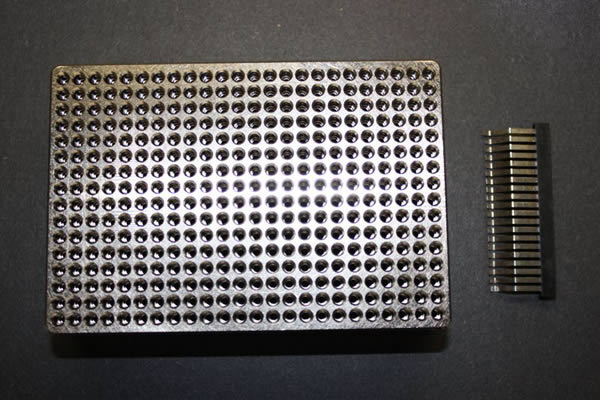

Wire EDM is commonly used in the manufacture of precision components such as extrusion dies, blanking punches, medical device parts, aerospace components, and intricate tooling. In the wire electrical discharge machining process, a thin electrode wire—typically made of brass or layered copper—follows a meticulously programmed path to create highly accurate cuts in conductive materials. While standard wire diameters range from 0.004" to 0.012" (0.1 mm to 0.3 mm), the process can accommodate a variety of wire sizes to suit different project requirements, including micro-EDM for ultra-fine features or large-scale EDM for heavy-duty industrial applications.

How Does Wire EDM Work?

Wire EDM, also known as wire-cut EDM or wire cutting EDM, utilizes a computer-controlled (CNC) process to guide a continuously fed wire through a submerged workpiece. The process begins by either threading the wire through an existing hole or starting from the edge of the material. When voltage is applied, a rapid sequence of electrical discharges (sparks) occurs between the wire and the workpiece, vaporizing and melting minute areas of material. These craters form the cut path, and the de-ionized water flushes away debris while maintaining thermal stability.

Unlike conventional machining methods, the wire and the workpiece never make physical contact. This non-contact machining eliminates mechanical stresses and enables the production of complex shapes, fine tolerances, and sharp internal corners. The CNC programming allows for intricate contours, tapers, and variable profiles at both the top and bottom of a component, making the process ideal for detailed mold making, precision stamping dies, and aerospace parts.

Depending on the desired finish and accuracy, the workpiece may be cut in multiple passes. The initial pass, known as rough cutting, removes most of the material. Subsequent skimming or finishing passes refine the dimensions and surface finish, achieving high levels of precision often measured in microns. This capability is essential for industries requiring tight tolerances and mirror-like surface qualities.

Key Components of a Wire EDM System

- CNC Control System – The CNC (Computer Numerical Control) system manages the entire EDM machining process. It automates the cutting sequence, controls the movement of the wire electrode, and ensures consistent accuracy and repeatability for complex geometries.

- Power Supply Unit – The power supply provides precise electrical pulses to the wire and workpiece, regulating the energy intensity and frequency of discharges. Advanced EDM power supplies offer programmable pulse settings to optimize material removal rates (MRR), surface roughness, and minimize electrode wear.

- Wire Electrode – Acting as the cutting tool, the wire electrode's diameter and composition are selected based on the workpiece thickness, desired accuracy, and material properties. Common wire materials include brass, copper, coated wires, and specialty alloys for enhanced performance and reduced wire breakage.

- Dielectric Medium – The machining tank is filled with de-ionized water, which serves as the dielectric fluid. This medium insulates the wire and workpiece, controls spark formation, cools the process, and continuously removes microscopic particles to achieve smooth surfaces and avoid secondary discharges.

- Servo System – Precision motors and servo controls maintain the optimal gap between the wire and the workpiece, preventing mechanical contact and ensuring consistent spark generation. This is crucial for maintaining part quality and preventing wire breakage.

- Workpiece Holder/Fixture – Robust fixturing ensures the workpiece remains securely positioned during machining, allowing for repeatable and accurate cuts, even on intricate or multi-axis projects.

Materials That Can Be Cut Using EDM Wire

One of the primary advantages of wire EDM is its ability to machine any electrically conductive material, regardless of hardness or toughness. This versatility makes wire EDM indispensable across a wide range of industries, including aerospace, medical device manufacturing, automotive, electronics, and tool and die making.

Common materials processed using wire EDM include:

- Tool Steels (D2, A2, H13, etc.) – Ideal for die making, stamping tools, and injection mold components.

- Stainless Steels – Used in medical instruments, aerospace parts, and food processing equipment.

- Titanium and Titanium Alloys – Preferred for lightweight, high-strength components in aerospace and medical implants.

- Aluminum and Aluminum Alloys – Used for rapid prototyping and precision electronic housings.

- Brass and Copper – Commonly used for electrical contacts, connector parts, and decorative applications.

- Superalloys (Inconel, Hastelloy, Waspaloy, etc.) – Essential for turbine blades, jet engine parts, and high-temperature environments.

- Carbide – Used in wear-resistant tooling and precision dies.

Because the process does not generate mechanical stresses or heat-affected zones (HAZ), wire EDM is suitable for parts requiring high dimensional stability, fine finishes, and minimal distortion. If you are uncertain whether wire EDM is suitable for your material, ask: Can my material be cut using EDM wire? Our team can evaluate your specific requirements and suggest the optimal EDM process or alternative machining solutions.

Common Applications of Wire EDM

Wire EDM is trusted for a diverse array of high-precision applications. Its ability to achieve intricate, burr-free cuts with exceptional accuracy makes it invaluable for industries with demanding quality and tolerancing standards. Typical applications include:

- Tool & Die Manufacturing – Creating extrusion dies, blanking punches, progressive stamping dies, and forming tools with tight tolerances and complex geometries.

- Mold Making – Producing detailed plastic injection molds, die-casting molds, and precision cavities for mass production.

- Medical Device Components – Manufacturing surgical instruments, orthopedic implants, and micro-scale parts from biocompatible alloys.

- Aerospace Components – Fabricating lightweight, high-strength parts such as turbine blades, fuel system components, and airframe brackets.

- Automotive & Motorsport – Producing transmission gears, fuel injector parts, and intricate drivetrain elements.

- Electronics & Semiconductors – Cutting lead frames, connectors, and micro-components for circuit boards and microelectromechanical systems (MEMS).

- Prototyping and Custom Parts – Allowing rapid iteration of new designs and fast turnaround of one-off or low-volume precision parts.

Are you searching for wire EDM solutions for your project? Explore our directory of trusted EDM machining companies to find a partner that specializes in your industry or application. Browse EDM machining service providers to get started.

Advantages of Wire EDM Machining

- Design Flexibility – Capable of producing intricate shapes, sharp inside corners, and fine details unattainable by conventional machining or laser cutting.

- Exceptional Accuracy – Achieves tolerances as tight as ±0.0001" (2.5 microns), essential for precision assemblies and critical components.

- Superior Surface Finish – Multiple skimming passes deliver mirror-like finishes, with surface roughness (Ra) values as low as 0.1 microns, reducing or eliminating the need for secondary polishing.

- No Tooling or Physical Contact – Eliminates tool wear, burr formation, and introduces no mechanical stresses or thermal distortion to the workpiece.

- Minimal Burrs and Clean Edges – Produces virtually burr-free parts, reducing post-processing and manual finishing.

- Material Versatility – Machines any conductive material, from hardened tool steels to exotic alloys, without loss of precision.

- Efficient Prototyping and Low-Volume Production – Rapidly produces prototypes and small batches with minimal setup time and no need for custom tooling.

- Cost-Effective for Complex Parts – Reduces labor and tooling costs for intricate components, especially when compared to traditional milling, turning, or grinding.

Considering whether wire EDM is the right choice for your next project? Compare the benefits of wire EDM vs. traditional machining or request a quote from expert providers.

Limitations and Considerations

While wire EDM offers outstanding precision and versatility, it's important to be aware of its limitations and ideal use cases. The process is restricted to electrically conductive materials and is generally slower than conventional milling or laser cutting when removing large volumes of material. However, for fine features, tight tolerances, and complex geometries, wire EDM is often the superior choice. Part thickness, wire diameter, and machine capabilities may also influence maximum part size and achievable accuracy. For thicker or harder components, specialized wire types or multiple passes may be required.

Are you unsure if wire EDM is suitable for your application? Contact our team to discuss your project requirements and receive expert recommendations tailored to your material, tolerancing, and production needs.

Factors to Consider When Choosing a Wire EDM Service Provider

Selecting the right wire EDM company is critical to achieving your desired quality, lead time, and cost objectives. When evaluating potential partners, consider the following factors:

- Experience with Your Material and Application – Does the provider have a track record of machining your specific material type or part geometry?

- Machine Capabilities and Tolerances – Can their equipment accommodate your part size, complexity, and tolerance requirements?

- Quality Assurance and Certifications – Look for ISO 9001, AS9100, or medical device certifications as evidence of rigorous process controls and documentation.

- Lead Times and Capacity – Does the provider offer fast turnaround and sufficient capacity for your production volume?

- Value-Added Services – Some EDM shops offer design assistance, CAD/CAM programming, secondary operations (deburring, finishing), and assembly support.

- Customer Reviews and Case Studies – Review testimonials, project case studies, or references to gauge customer satisfaction and project success.

For the best results, compare multiple wire EDM companies using our comprehensive directory. Each company’s profile highlights their experience, equipment, and specialties. Use our patented website previewer to evaluate capabilities and request quotes from multiple providers using a single, convenient RFQ form.

Wire EDM for Prototyping, Production, and Repair

Wire EDM is not limited to high-precision production runs. Its flexibility makes it an excellent choice for rapid prototyping, short-run manufacturing, and even precision repair and refurbishment of tooling and dies. Whether you need a single complex part, iterative design changes, or restoration of worn features on critical components, wire EDM provides unmatched accuracy and repeatability. The process easily adapts to changing design files, making it ideal for industries with evolving requirements or frequent engineering changes.

Looking for quick-turn EDM prototyping or precision repair services? Find providers specializing in fast turnaround and specialized repair solutions.

Frequently Asked Questions About Wire EDM

- What is the thickest part that can be cut with wire EDM?

Most modern wire EDM machines can cut parts several hundred millimeters thick, depending on machine capacity and wire type. Consult with your provider for specific maximums. - How accurate is wire EDM?

Wire EDM routinely achieves tolerances of ±0.0001" (2.5 microns) or better, making it suitable for high-precision applications such as molds, dies, and medical devices. - Does wire EDM cause heat-affected zones or material distortion?

No, the process uses rapid electrical discharges and dielectric cooling, resulting in minimal thermal distortion and no heat-affected zones. - Can non-metallic materials be cut with wire EDM?

Only electrically conductive materials can be machined. Some ceramics with conductive coatings may be suitable—ask your provider about special requirements. - What industries benefit most from wire EDM?

Aerospace, medical device, automotive, mold and die, electronics, and general manufacturing industries all leverage wire EDM for its precision, flexibility, and repeatability. - How do I get a quote for my wire EDM project?

Use our RFQ form to submit your project details and receive competitive quotes from multiple qualified EDM providers.

Start Your Wire EDM Project Today

Wire EDM offers unmatched precision, versatility, and design freedom for manufacturers and engineers seeking to push the boundaries of what’s possible. Whether you need intricate stamping dies, complex aerospace components, medical device parts, or rapid prototypes, wire EDM delivers results that meet the highest standards for quality and accuracy.

Ready to experience the advantages of wire EDM machining? Contact our network of certified EDM machining companies to discuss your requirements, explore material and process options, and request a customized quote. Discover how wire EDM can enhance your manufacturing capabilities and accelerate your next project.

Aluminum Anodizing

Aluminum Anodizing EDM

EDM Electroless Nickel Plating

Electroless Nickel Plating EMI Shielding

EMI Shielding Heat Treating

Heat Treating Metal Coating Services

Metal Coating Services Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services